What is a battery series die-casting mold and what role does it play in the new energy industry?

Basic definition of battery series die-casting molds

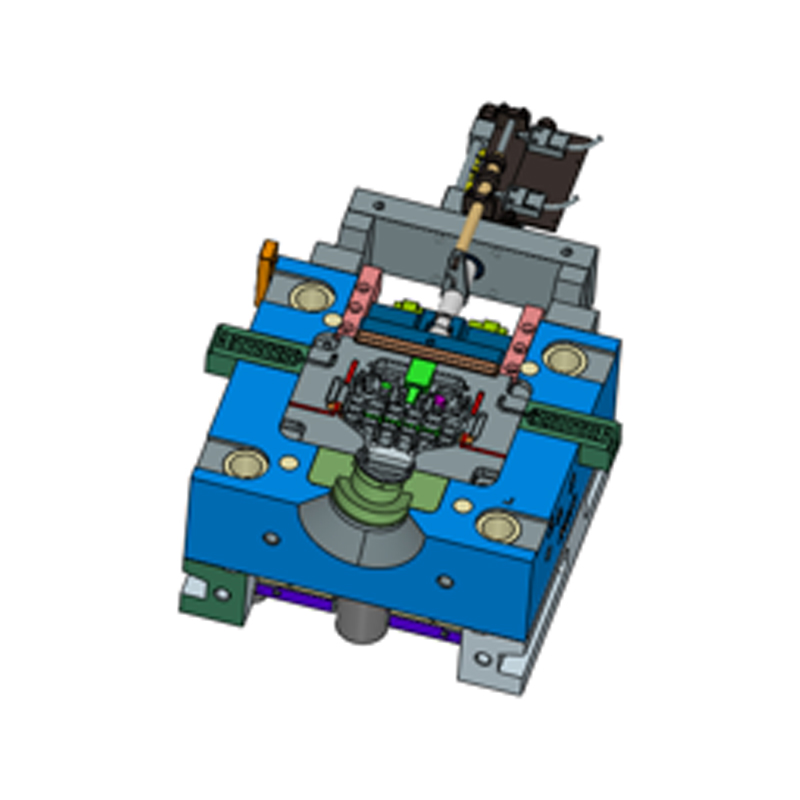

Battery series die-casting molds refer to die-casting molds specially used for the production of various battery shells, battery module brackets, battery bottom brackets, battery pack connection parts and other structural parts. It is usually based on lightweight materials such as aluminum alloys and magnesium alloys. By injecting liquid metal into the mold cavity under high pressure, the mold can complete the molding of parts with complex structures and high dimensional accuracy in a short time. This type of mold mainly serves the key metal structural parts involved in power batteries, energy storage batteries and battery systems.

Structural demand of new energy industry drives mold development

With the continuous promotion of new energy vehicles and energy storage equipment, the expansion of power battery system production capacity has directly led to high requirements for die-casting parts such as shells, module racks, and battery connectors. Battery die-casting molds bear the dual tasks of structural accuracy and molding efficiency in this process, and are the key process link for connecting material molding and product structure realization. For example, the battery pack shell for new energy vehicles requires high strength, good heat dissipation, low weight and a certain degree of airtightness. These performance indicators depend largely on the design level and processing accuracy of the mold.

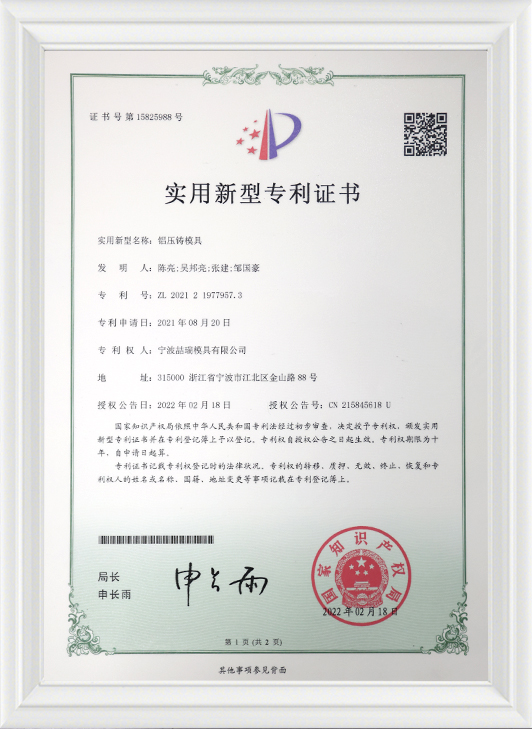

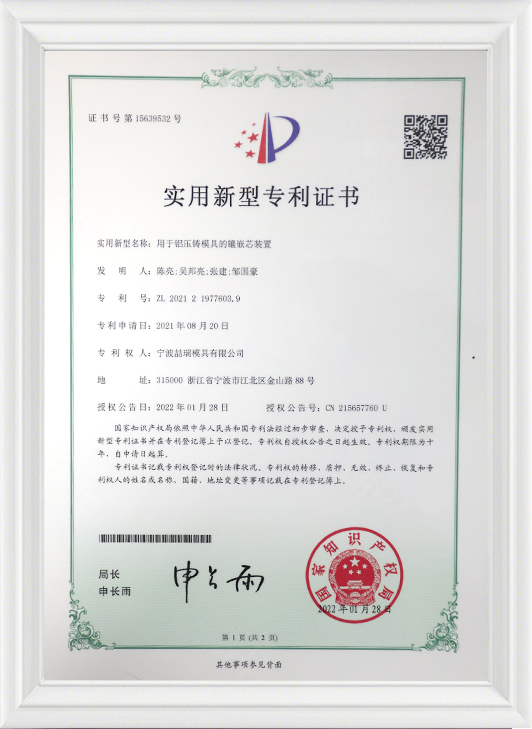

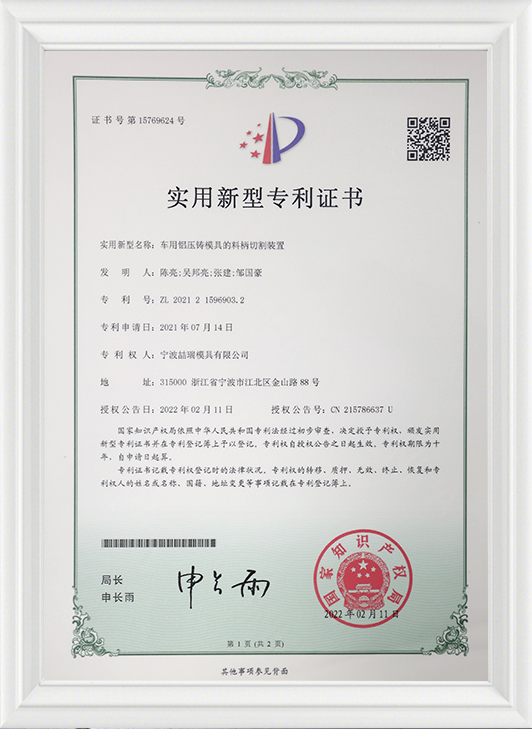

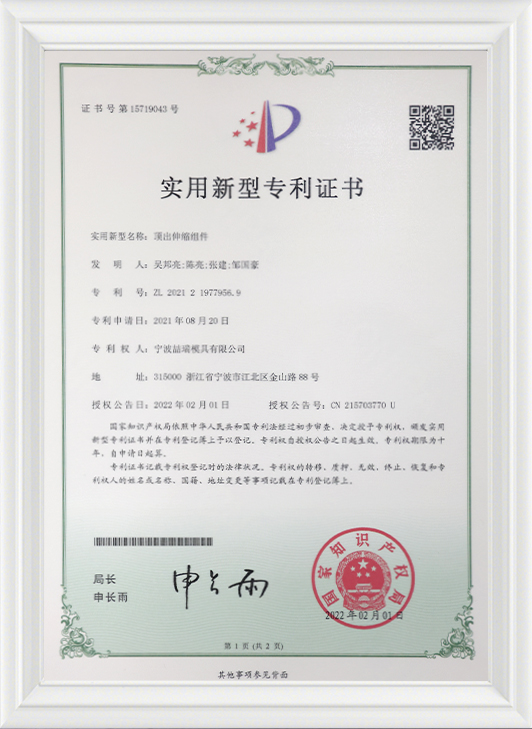

Ningbo NKT Tooling Co., Ltd.'s involvement in the battery mold field

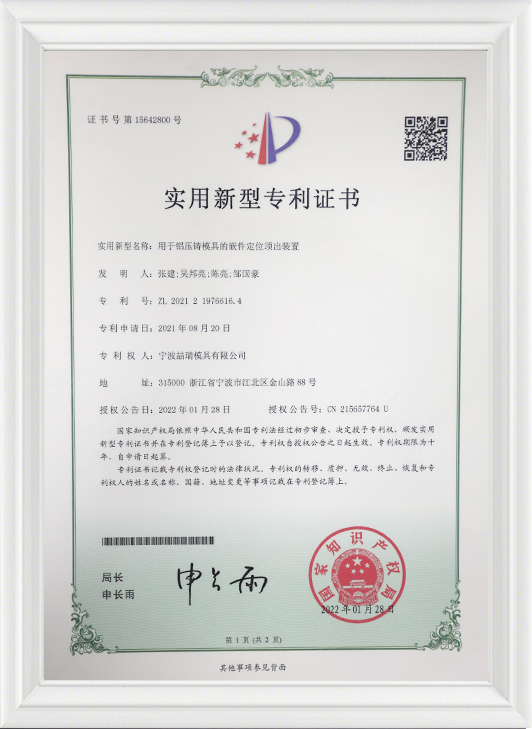

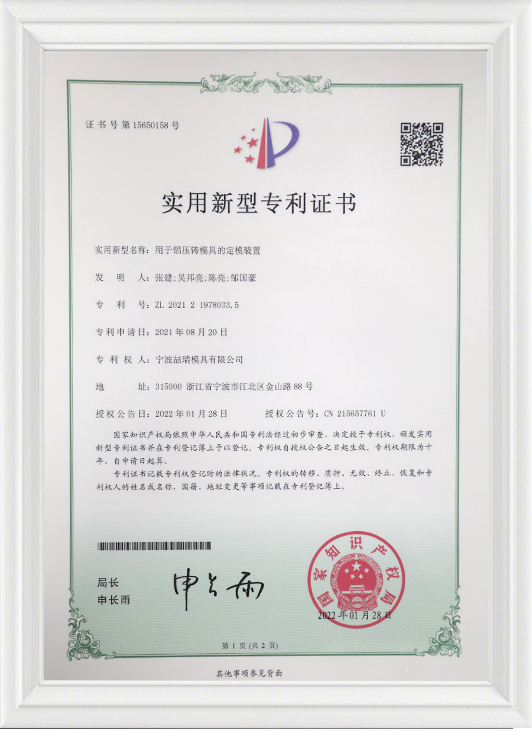

Ningbo NKT Tooling Co., Ltd. has been focusing on the design and manufacture of aluminum, magnesium, and zinc alloy molds since 2009, and has gradually accumulated more experience in die-casting molds for new energy battery shells. Relying on its 6,000 square meters of modern manufacturing plants and a technical team of more than 80 people, NKT Tooling can produce hundreds of sets of high-precision molds for battery systems every year, serving customers in multiple industries such as automobiles, energy storage equipment, and industrial power systems, and can provide structural optimization suggestions and die-casting solutions according to different application requirements.

Typical application structure of battery die-casting molds

This type of mold is often used to manufacture key structural parts such as power battery shells, module brackets, cooling base plates, and battery connection end plates. These structural parts often have the characteristics of large wall thickness variations, many structural ribs, and complex assembly interfaces, which put forward high requirements on the mold's gate system, exhaust method, cooling layout, etc. For example, the integrated battery pack shell requires the mold to have both large-area molding capabilities and good flow filling control capabilities.

The influence of materials and processes on mold performance

Battery series die-casting molds are mostly made of high-strength hot-working die steel such as H13 and 8407 to cope with the thermal shock and wear problems caused by aluminum and magnesium alloys during the die-casting process. In terms of processing technology, in order to improve the life of the mold and the accuracy of the die-casting parts, the mold manufacturing needs to undergo multiple heat treatments, surface strengthening (such as nitriding, PVD coating) and CNC precision machining. NKT Tooling is equipped with multiple high-speed machining centers and heat treatment equipment in these links to ensure that the mold structure and performance meet the requirements of the die-casting production line.

The auxiliary role of molds in the safety and performance of new energy batteries

The power battery system has high requirements for safety and thermal management. The molding quality of the mold directly affects the sealing, structural integrity and heat dissipation capacity of the die-casting parts. A mold with optimized structure, scientific flow channel and smooth exhaust can reduce the internal pores, cold shut and deformation problems of the product, thereby improving the safety and service life of the battery module. This indirect support is one of the roles that molds cannot be ignored in the new energy industry.

Sustainable application trend of battery molds

As the new energy industry moves towards standardization and integration, battery die-casting molds are also gradually developing in the direction of "multi-cavity", "modularization" and "convenient mold change". Some customers have begun to put forward requirements such as fast mold change, online detection and automatic debugging, prompting mold manufacturing companies to continuously optimize structural design and processing methods. NKT Tooling is also improving product responsiveness through digital design software and simulation analysis tools to provide customers with more efficient mold solutions.

How to determine whether a battery die-casting mold needs regular maintenance or replacement of parts?

Observe whether fatigue cracks appear on the surface of the mold

Battery die-casting molds are operated under high temperature and high pressure conditions for a long time, and thermal fatigue cracks are prone to appear on their surfaces. These cracks mostly develop gradually along the surface of the mold cavity or the edge of the parting surface. They are difficult to detect with the naked eye at the beginning, but once they deepen, they are easy to affect the molding quality of the die-casting. When it is found that the mold has tiny cracks on the surface of the die-casting during the production process or crack lines are observed after the mold is disassembled, it is necessary to carry out maintenance in time to prevent the cracks from expanding to the point where they cannot be repaired.

Check the changes in the dimensional stability of the die-casting

Mold wear or loose positioning mechanism will cause dimensional deviations in the die-casting, especially for structural parts such as battery shells that require high matching accuracy. Any slight error may affect assembly. In the normal production process, if it is found that the dimensional tolerance of the die-casting is gradually approaching the boundary, or the consistency of different batches of products decreases, it means that key components such as the mold positioning pins, guide pillars, and cores may be worn, and it should be checked in time whether they need to be repaired or replaced.

Determine whether the mold exhaust system is unobstructed

The exhaust groove and exhaust hole are important auxiliary structures in the mold, which determine whether the gas inside the mold cavity can be discharged in time. If the exhaust system is blocked by carbon deposits and metal residues, it will cause defects such as pores and cold shuts in the die castings. Regularly observe whether the die castings have frequent pore defects, which can be used as a basis for judging whether the mold exhaust system needs to be cleaned. In addition, if the mold exhaust groove is roughened or collapsed, it also needs to be polished or repaired.

Monitor the decline in the efficiency of the mold cooling system

Battery die-casting molds mostly use internal cooling water circuits for temperature control to keep the molding temperature stable and extend the life of the mold. If the cooling system has problems such as scale blockage, pipeline aging or leakage, it will cause uneven cooling, causing deformation of the die casting or excessive local temperature rise of the mold. Through regular temperature measurement, analyze whether the temperature distribution of various parts of the mold is abnormal, and determine whether the cooling system needs to be maintained or replaced.

Check whether the mold moving parts are delayed or stuck

Common moving parts in battery molds include core pull sliders, push rods, ejectors, etc. These structures are repeatedly operated every time the mold is opened and closed, and are prone to wear or insufficient lubrication. Once the movement is not smooth, it may cause problems such as mold jamming, mold deviation, and poor ejection. Operators should pay attention to whether incomplete ejection and slow return of the slider frequently occur during the die-casting process, and promptly inspect the guide rails, limit mechanisms, springs and other parts.

Regularly track the production and use cycle and life limit of the mold

At the beginning of the design, each set of battery die-casting molds will have a theoretical service life set, generally based on the production mold times, such as 100,000 molds, 150,000 molds, etc. As the number of production times increases, the mold heat load accumulates and structural fatigue is inevitable. Therefore, Ningbo NKT Tooling Co., Ltd. usually recommends that customers establish a mold use record account, regularly check the cumulative mold times, and evaluate in advance whether the overall renovation or replacement of parts is required when approaching the upper limit of use.

Use professional testing methods to determine the internal wear

Some wear positions of the mold (such as the bottom of the deep cavity and the bottom of the core) are difficult to observe directly in daily use. At this time, equipment such as a three-coordinate measuring instrument, a laser scanner or an industrial endoscope can be used for detection to analyze parameters such as mold cavity wear depth and concentricity changes, so as to determine whether reprocessing or replacement of worn parts is required. Ningbo NKT Tooling Co., Ltd. also provides relevant technical support and periodic inspection suggestions after the mold is delivered to the customer to help customers extend the service life of the mold.

Early warning of abnormal surface phenomena of die-casting parts

When the mold is partially damaged, worn or loosely assembled, the die-casting parts often have abnormal burrs, flash, deformation, surface scratches and other problems. In particular, structural parts such as battery shells have high requirements for appearance, and subtle defects in die-casting parts should be used as the first signal for mold maintenance. It can be combined with the data feedback from the quality inspection department as a supplementary basis for judging the health status of the mold.

Establish a systematic mold maintenance plan

Regular maintenance is an important way to ensure the performance of battery die-casting molds. It usually includes steps such as cleaning the mold cavity, checking accessories, lubricating sliding mechanisms, tightening connectors, and polishing the demolding surface. Ningbo NKT Tooling Co., Ltd. recommends that customers formulate different levels of maintenance content on a daily, weekly, and monthly basis based on the complexity of the mold structure and the frequency of use to ensure that the mold is always in a stable state and reduce the risk of production stoppage due to sudden failures.

English

English 中文简体

中文简体