What are the main advantages of aluminum alloy die casting molds produced by NKT Tooling?

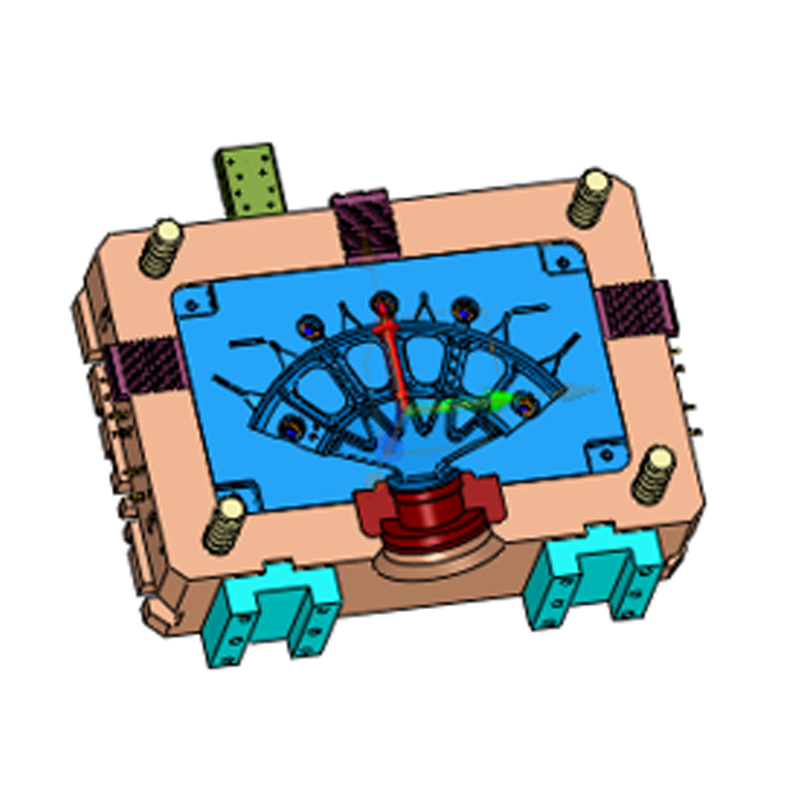

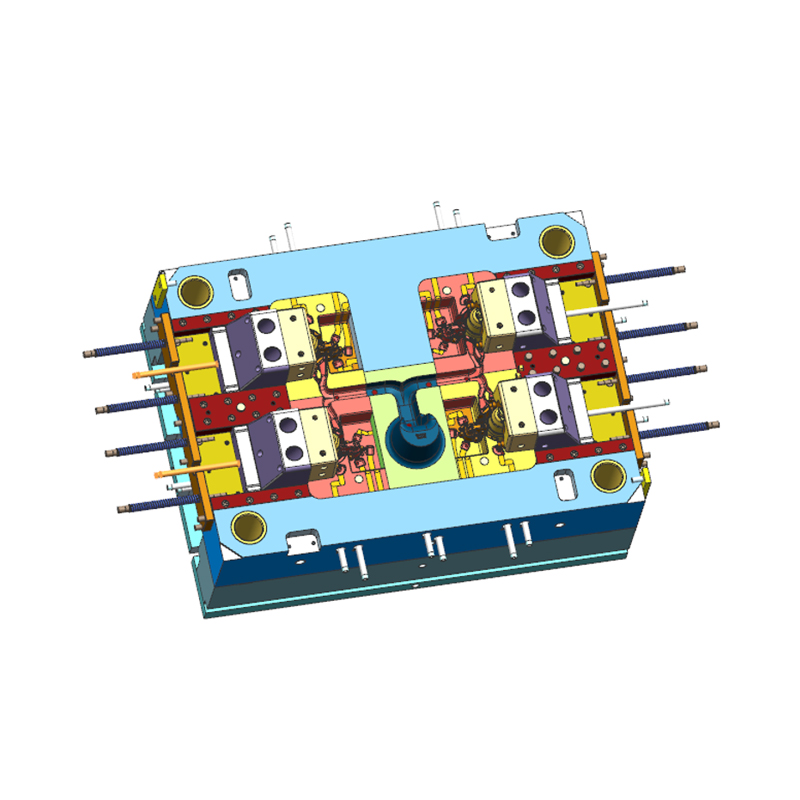

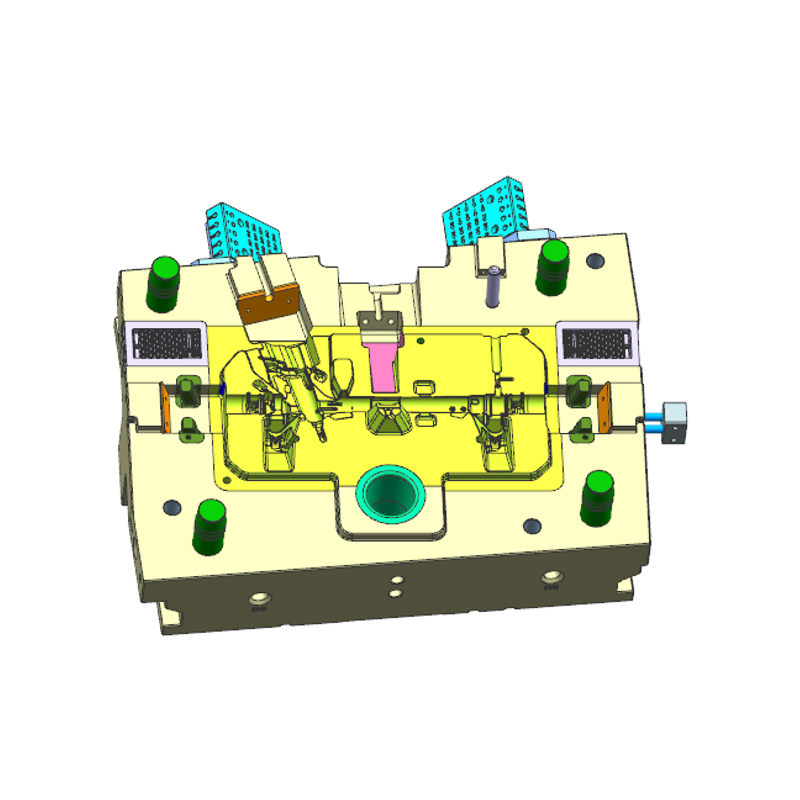

Refined structural design capabilities

Ningbo NKT Tooling Co., Ltd. has an experienced technical team, including 15 engineers with middle and senior technical titles and more than 30 professional engineering and technical personnel. In the design of aluminum alloy die-casting molds, the company has the ability to decompose and model complex parts, accurately analyze the product drawings provided by customers, and reasonably arrange key structures such as parting lines, gate systems, and exhaust systems, thereby improving the consistency and precision of die-cast products.

Material selection is exquisite

In order to ensure that the mold has a long service life under high pressure and high temperature conditions, Ningbo NKT Tooling Co., Ltd. insists on using high-strength mold steel in the selection of mold materials. Commonly used materials such as H13, 8407, etc., after vacuum heat treatment and quenching and tempering process treatment, have strong thermal fatigue resistance, effectively avoid mold cracking, collapse angle and other problems, and extend the mold life cycle.

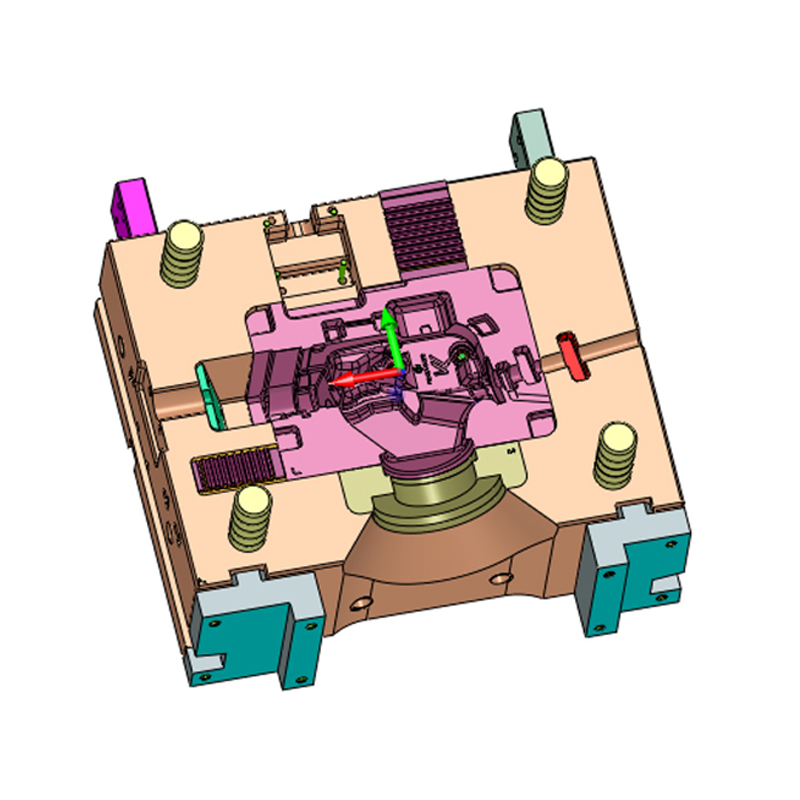

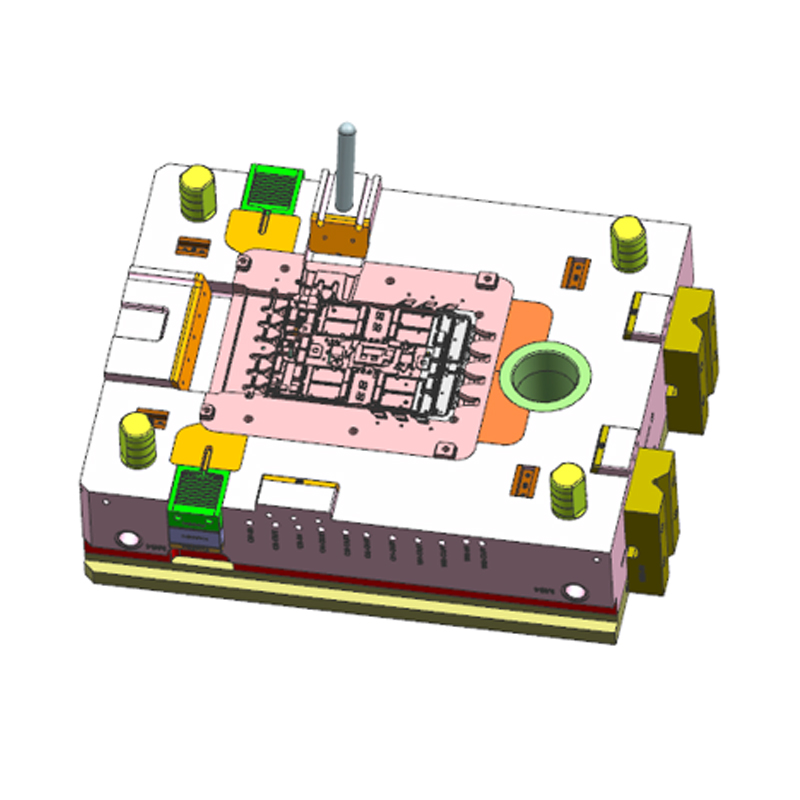

Precision machining ensures dimensional stability

In the manufacturing process, the company introduced high-precision CNC machining equipment, including five-axis machining centers, slow wire cutting, CNC milling and other processing methods. For core parts such as cavity, parting surface, and guide structure, Ningbo NKT Tooling Co., Ltd. uses a combination of precision machining and manual polishing to control the dimensional error of the mold within a small range, providing a guarantee for the consistency of die-cast products.

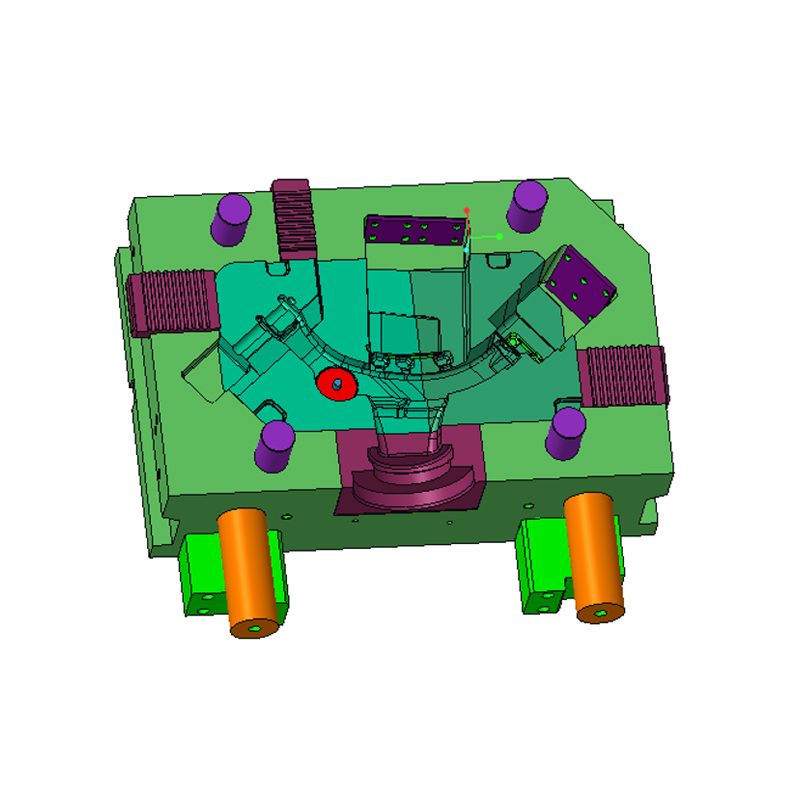

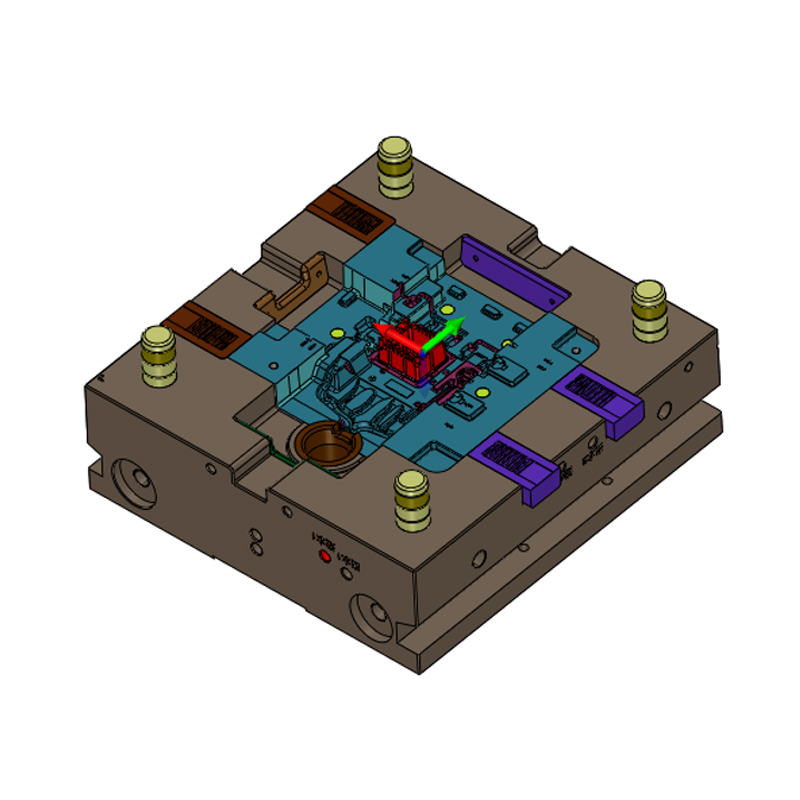

Focus on mold cooling and exhaust system design

During the die-casting process of aluminum alloy, the design of the mold cooling system directly affects the cooling speed and deformation control of the product. The company uses three-dimensional dynamic simulation and optimization in the layout of mold cooling water channels to ensure the thermal balance of each area of the mold. At the same time, a reasonable exhaust structure also helps to reduce pores and slag inclusions and improve the surface quality of castings.

Supports diversified structural customization

Ningbo NKT Tooling Co., Ltd. has the ability to design and manufacture more than 300 sets of molds each year, and can provide single-cavity, multi-cavity, inclined top, insert, hot runner and other types of mold structures according to customer functional requirements. For highly complex and highly structurally integrated automotive parts, motor housings, communication housings and other products, the company can provide a one-stop solution from early solution analysis to later processing and delivery.

Adapt to the application requirements of multiple industries

The aluminum alloy die-casting molds manufactured by the company are widely used in many fields such as automobiles, communications, industrial equipment, medical and sports equipment. For different industry standards and precision requirements, Ningbo NKT Tooling Co., Ltd. can flexibly adjust the design strategy and manufacturing parameters to meet the functional requirements of lightweight, heat resistance, strength and other aspects.

Strict quality control system

During the mold manufacturing process, the company implements multiple quality inspection processes, including self-inspection during processing, functional inspection after assembly and trial mold, and final dimensional inspection. Use professional testing equipment such as three-coordinate measuring machines, hardness testers, and flaw detectors to ensure that each set of molds meets the technical standards set by customers.

Continuous technical support and after-sales service

Ningbo NKT Tooling Co., Ltd. not only provides mold manufacturing services, but also provides supporting technical services such as mold flow analysis, structural optimization suggestions, trial mold tracking, and mold maintenance guidance. After the customer puts the mold into production, if the customer encounters problems such as structural wear and efficiency reduction, the company can respond quickly and provide targeted technical support.

How does NKT Tooling ensure the accuracy and consistency of aluminum alloy die casting molds?

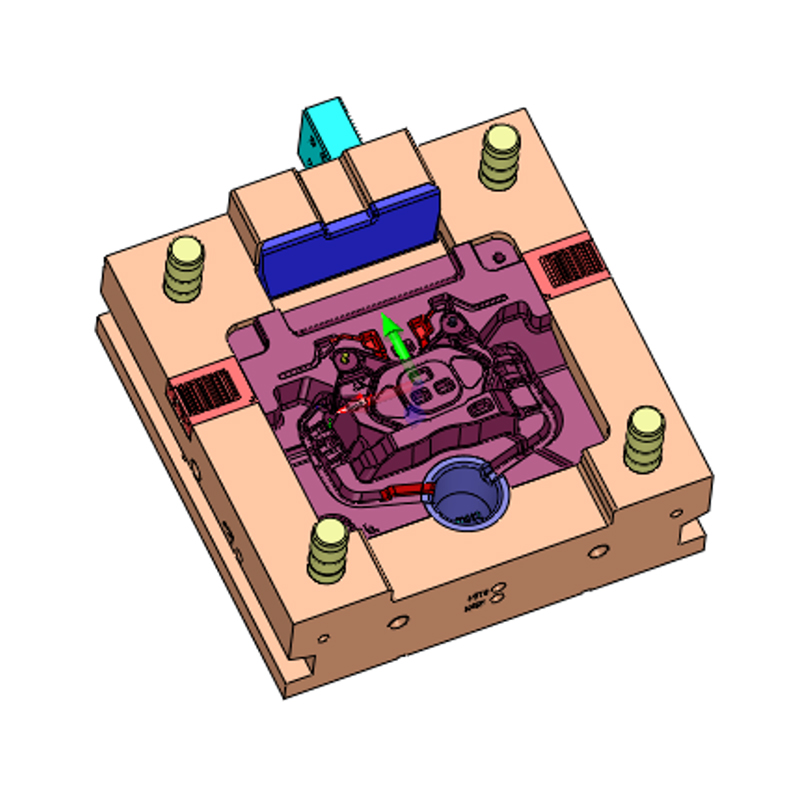

Precise preliminary design process

In the manufacturing process of aluminum alloy die-casting molds, preliminary design is the basis for ensuring accuracy and consistency. Ningbo NKT Tooling Co., Ltd. uses professional 3D modeling software (such as UG, Pro/E, AutoCAD, etc.) to model, part, structurally analyze and simulate mold flow for product drawings provided by customers. In the design stage, key parameters such as the force distribution, material flow path, exhaust position and cooling system of the mold are considered to ensure the reasonable structure of the mold and lay a stable foundation for subsequent precision machining and die-casting.

Strict material selection and processing technology

The dimensional stability and thermal fatigue resistance of the mold are directly related to the selected materials. Ningbo NKT Tooling Co., Ltd. mainly uses mold steel with good heat treatment performance (such as H13, 1.2344, etc.) in aluminum alloy die-casting molds, and undergoes professional heat treatment processes such as vacuum quenching and tempering to improve the hardness and toughness of the material, reduce the risk of deformation during repeated thermal expansion and contraction, and control accuracy fluctuations from the source.

High-precision CNC machining equipment

The company continues to invest in equipment configuration and is equipped with high-end machining equipment such as five-axis machining centers, CNC milling machines, EDM machines, and slow wire cutting. The use of these equipment enables high-precision machining of key structural parts such as cavities, sliders, inclined tops, and inserts, and the error is controlled within the micron range to ensure that the overall structure of the mold is precise and consistent with the molding effect.

Process control and self-inspection mechanism

During the processing, Ningbo NKT Tooling Co., Ltd. implements a segmented quality inspection mechanism. After each stage of processing is completed, the operator must perform dimensional self-inspection, including key point measurement, contour inspection, and fit tolerance calibration, to ensure that the output of each process is stable and qualified. This process control not only improves the overall accuracy, but also effectively avoids the problems caused by cumulative errors.

Mold assembly and fit debugging

During the mold assembly process, the clearance, sliding fit, and positioning accuracy of each component directly affect the operation effect of the mold. The company uses precision measuring tools (such as feeler gauges, micrometers, internal diameter gauges, etc.) to inspect the mating parts to ensure the closing accuracy between the moving mold and the fixed mold. At the same time, the dynamic debugging of the overall structure is carried out through the trial mold stage to adjust the mold closing accuracy and the sliding smoothness of the mold moving parts to achieve structural consistency and stability.

Mold flow analysis assisted optimization

Before formal processing, Ningbo NKT Tooling Co., Ltd. will conduct mold flow analysis on molds with complex structures or high molding requirements, and use software simulation to predict the flow state of aluminum liquid in the mold, cooling time, shrinkage risk, pore distribution and other factors, so as to adjust the mold structure parameters in advance, avoid dimensional instability problems that may be caused during the die casting process, and improve the consistency of die casting products.

Three-coordinate detection and quality data recording

After the mold is manufactured, the company uses a three-coordinate measuring instrument to conduct a final inspection of the key dimensions, and judges whether the mold meets the design tolerance requirements through data comparison and analysis of the coordinate points. In addition, the inspection data will be recorded in the quality system as a reference for later mold repair, adjustment or remanufacturing, and also provide customers with complete quality traceability information.

After-sales tracking and mold maintenance suggestions

During actual use, the mold will undergo multiple opening and closing and die-casting cycles, which is a continuous test of structural accuracy. Ningbo NKT Tooling Co., Ltd. provides mold maintenance suggestions and technical tracking during use, such as regular inspection of guide pin wear, cleaning of exhaust grooves, adjustment of cooling channels, etc., to help customers maintain the structural stability of the mold in long-term operation.

English

English 中文简体

中文简体