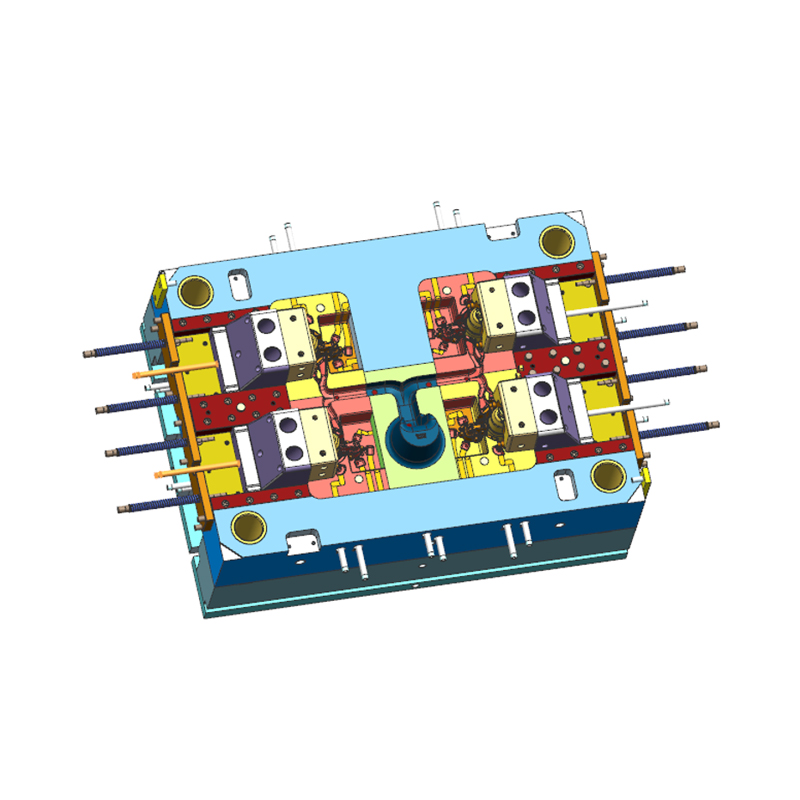

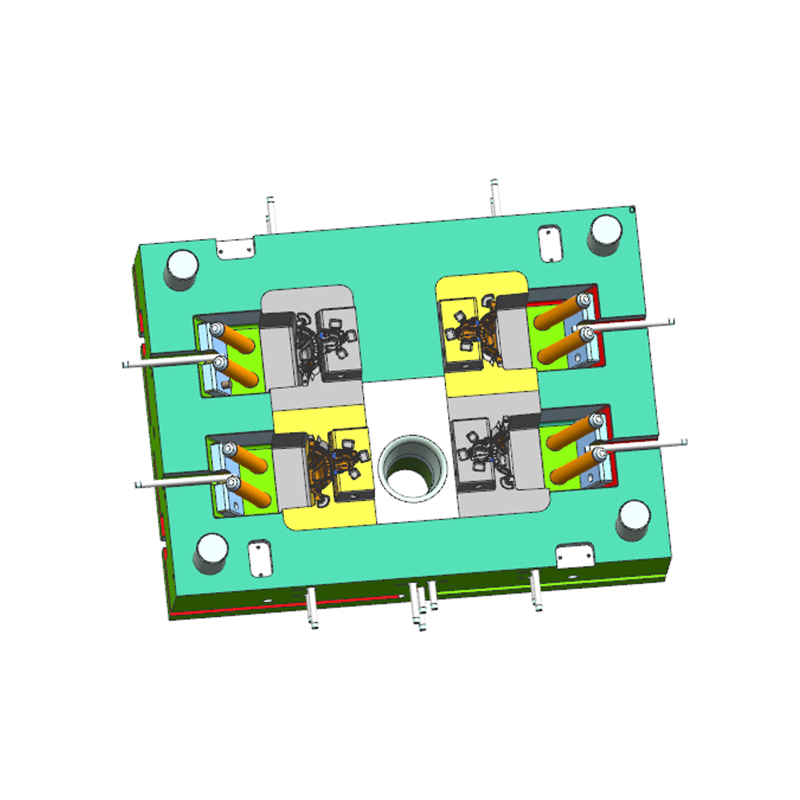

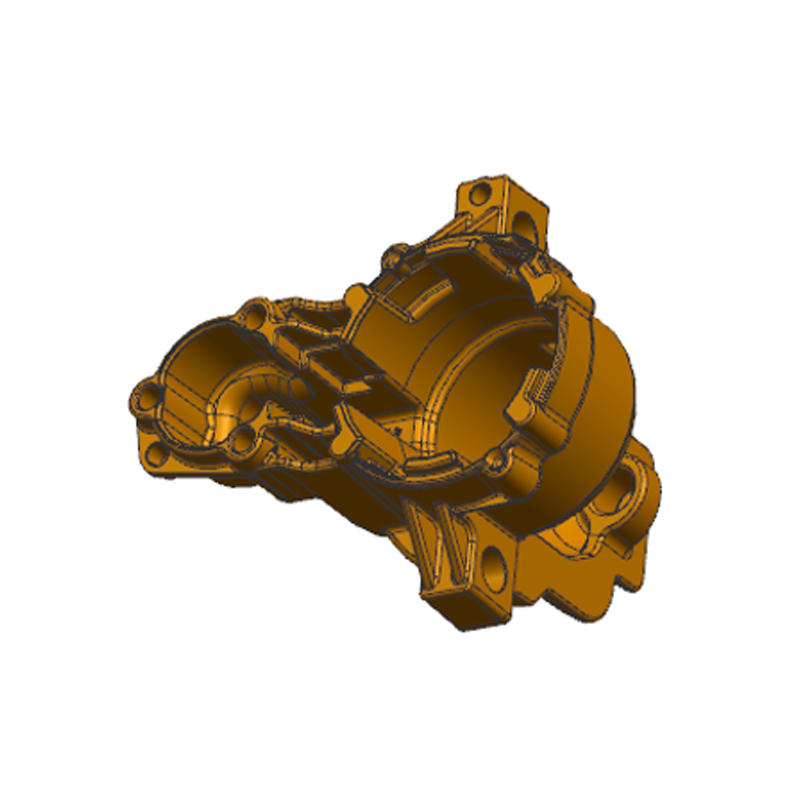

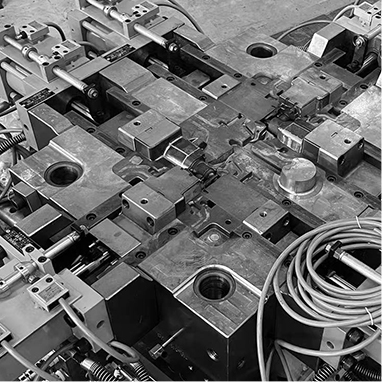

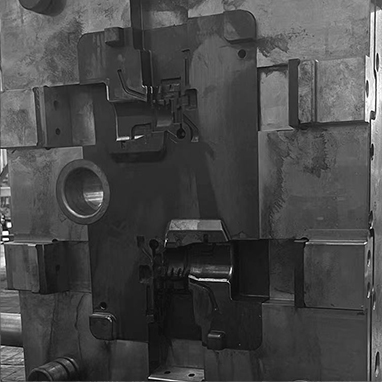

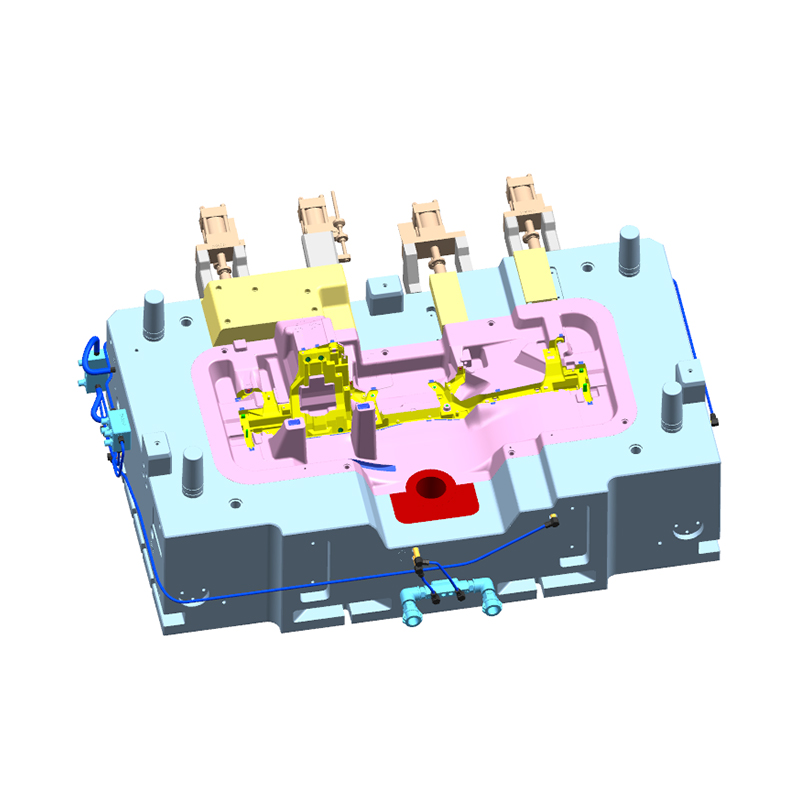

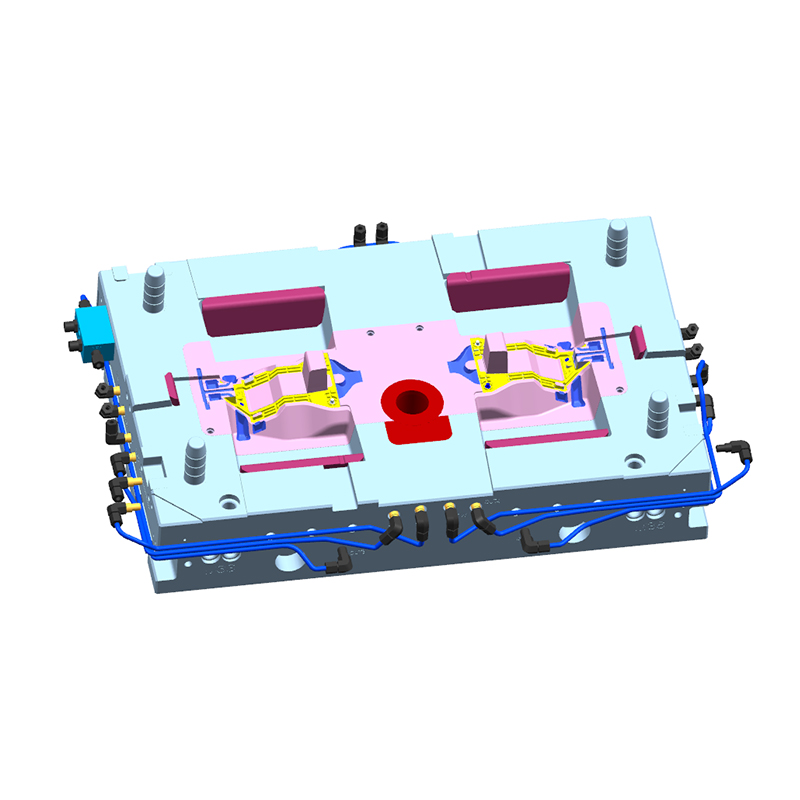

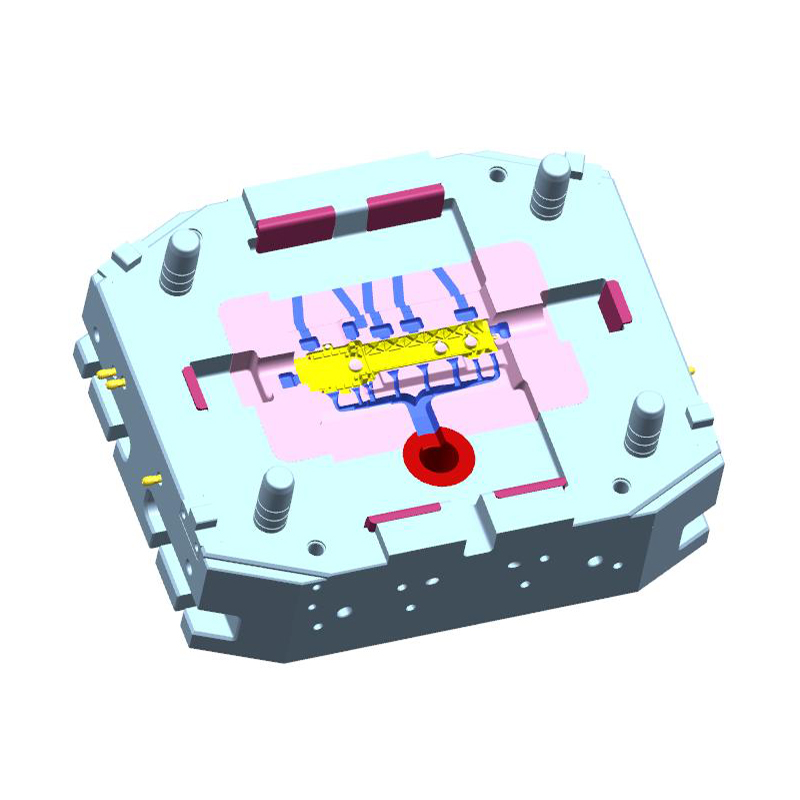

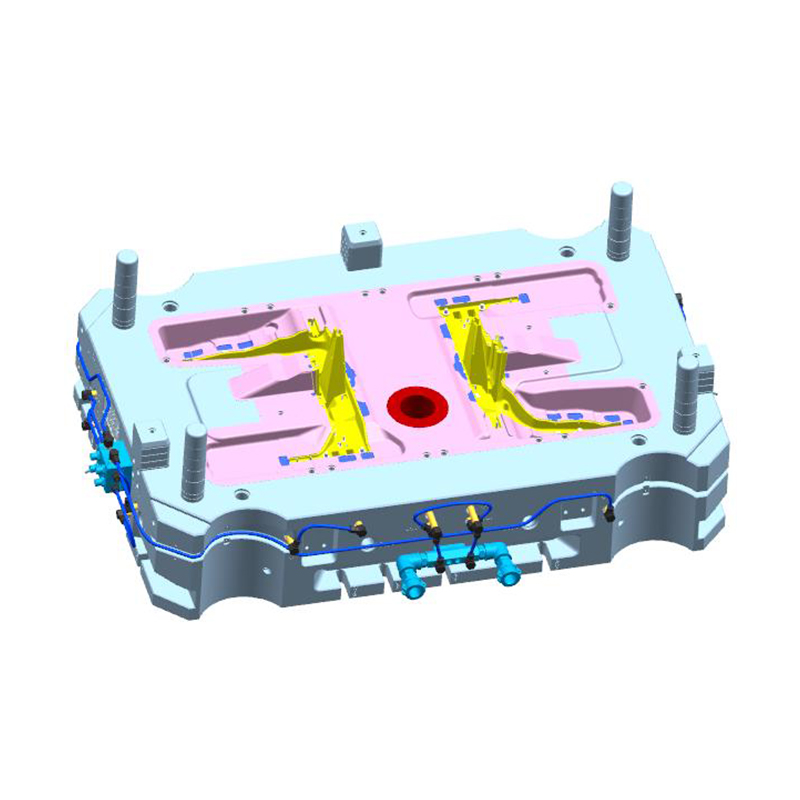

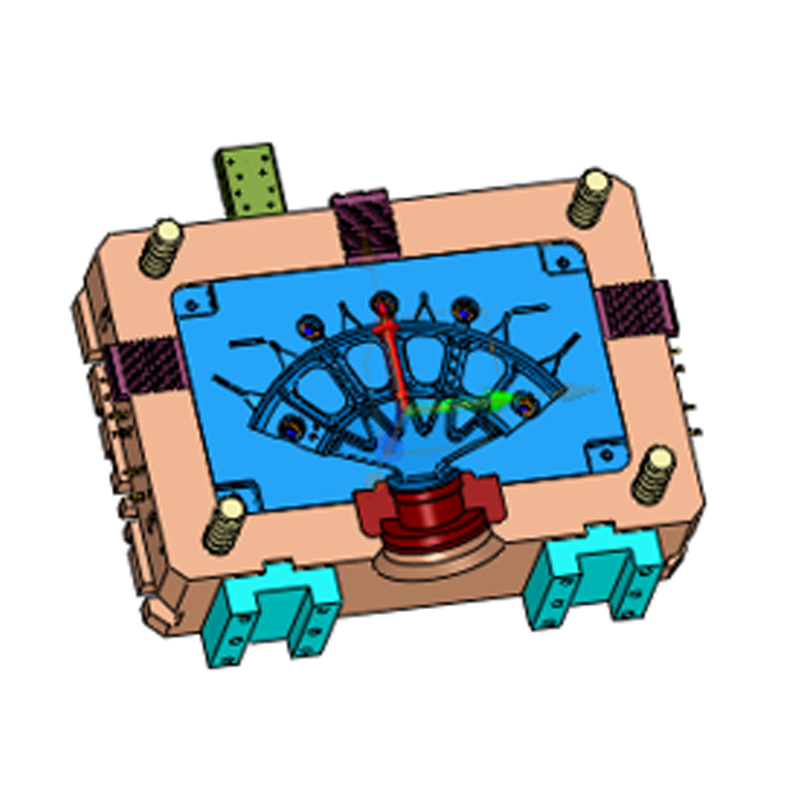

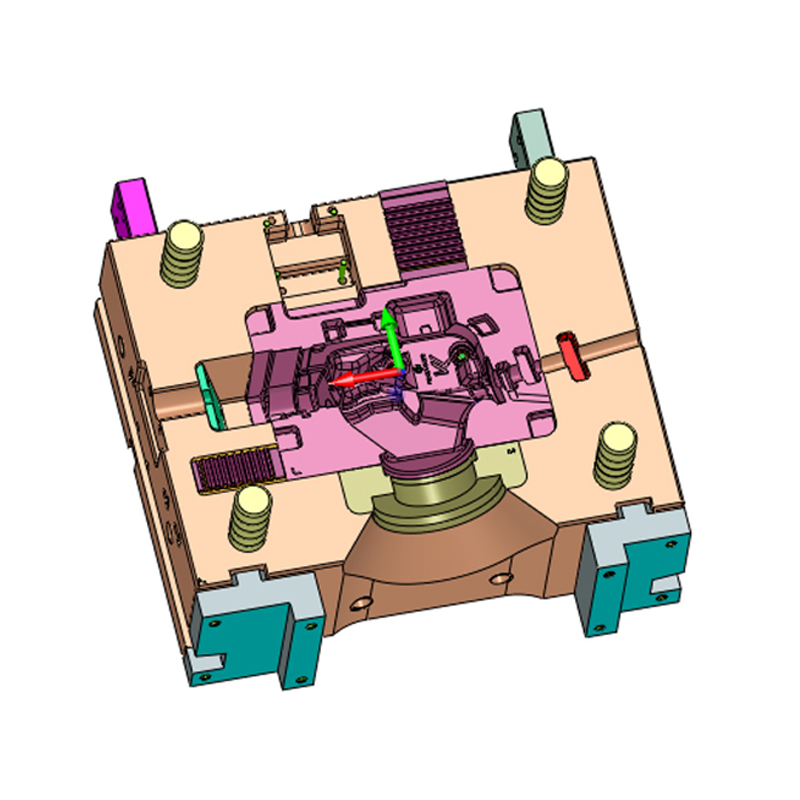

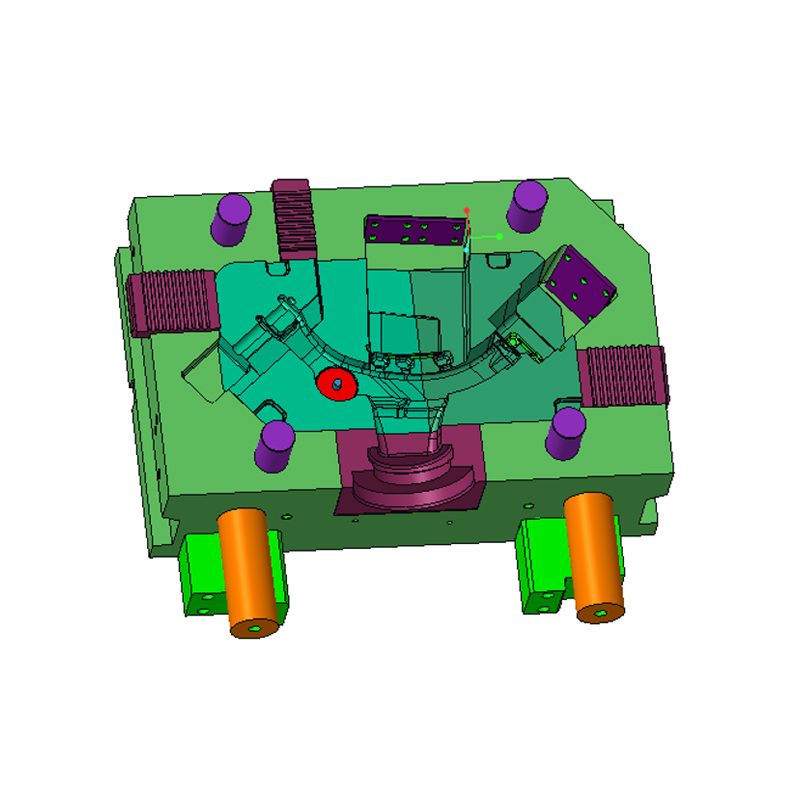

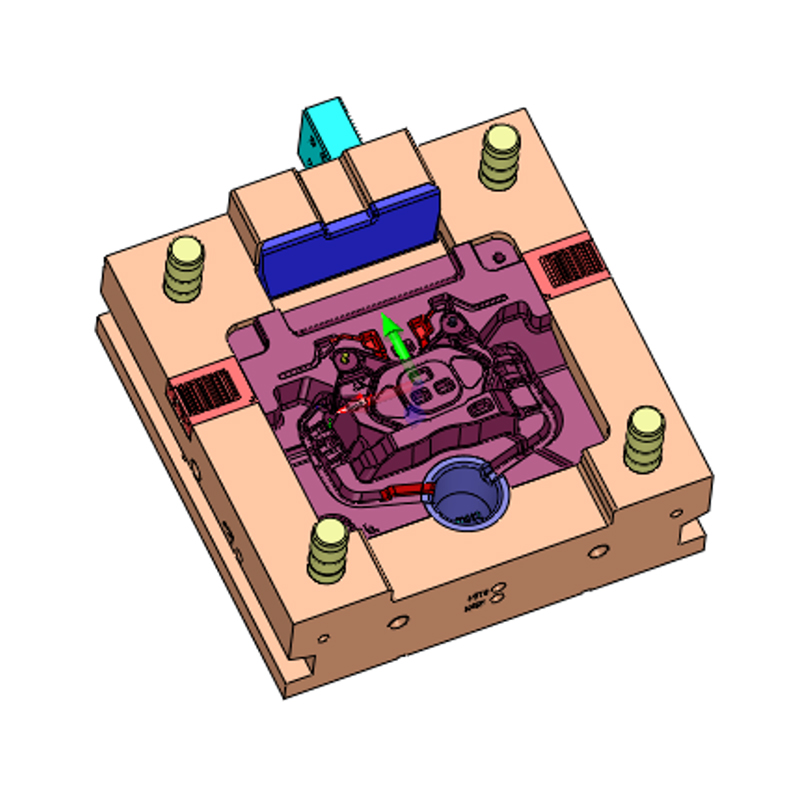

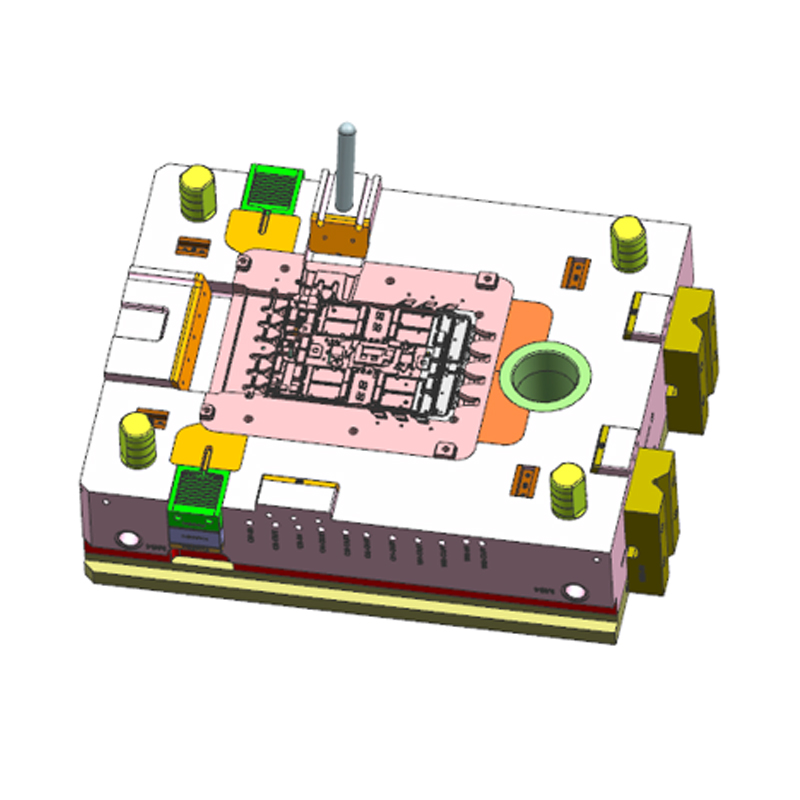

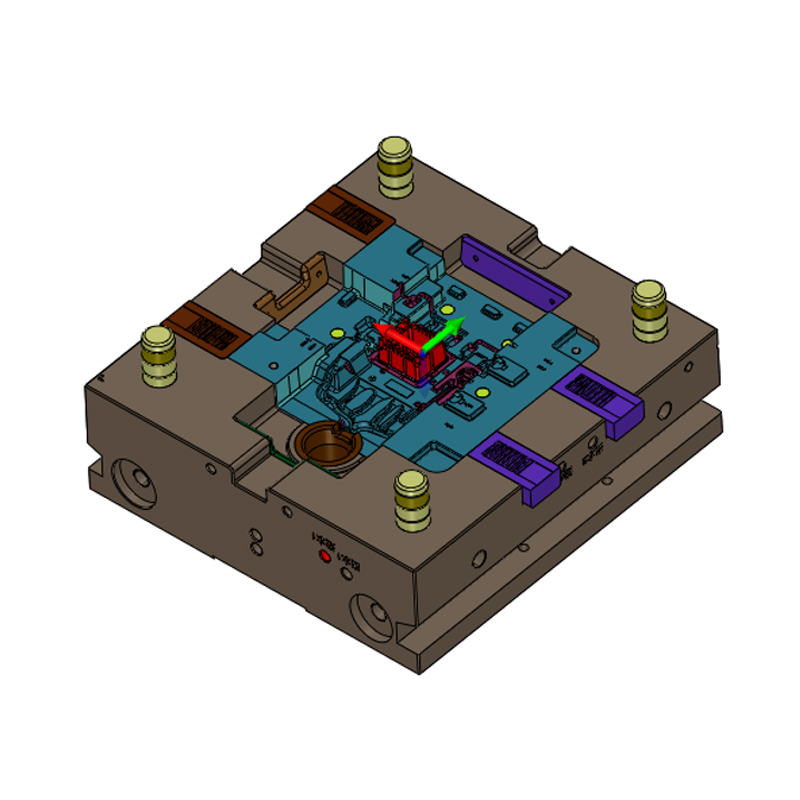

Ningbo NKT Tooling Co., Ltd. is China Aluminum Alloy Die-Cast Housing Manufacturers and Aluminum Alloy Die-Cast Housing Factory, founded in September 2009, NKT Tooling specializes in the design and manufacturing of aluminum, magnesium, and zinc alloy molds, as well as extrusion casting molds. Our products are widely used across various industries, including automotive, communications, industrial applications, and health and sports equipment, meeting the precise and diverse needs of our customers. The company has strong capabilities, with total assets of nearly 60 million yuan and a modern manufacturing facility covering approximately 6,000 square meters. Our team consists of over 80 professionals, including 15 senior engineers with intermediate or higher-level technical titles, and more than 30 specialized engineering and technical staff. With this talent pool, we are capable of designing and producing over 300 sets of high-precision molds annually, demonstrating our robust production capacity and technical expertise.

Importance of aluminum alloy die casting in the automotive industry As the automotive industry develops towards a more efficient and environmentally friendly direction, aluminum alloy, as an ideal lightweight material, has become an important part of modern automobile manufacturi...

READ MORE

English

English 中文简体

中文简体