What are the differences between casting molds for new energy vehicle series and traditional vehicles?

Differences in material requirements

As the trend of lightweight automobiles advances, new energy vehicles have increasing requirements for mold materials. Compared with traditional vehicles, new energy vehicles use a large number of lightweight materials such as aluminum alloys and magnesium alloys in their structural design, which places higher requirements on the heat resistance, wear resistance and molding stability of casting molds. Traditional vehicle molds are mostly used for the molding of steel parts or cast iron parts, while new energy vehicles tend to use light alloys with high thermal conductivity, high strength but easy to deform. Therefore, mold design needs to adapt to different shrinkage rates, thermal conductivity and metal fluidity.

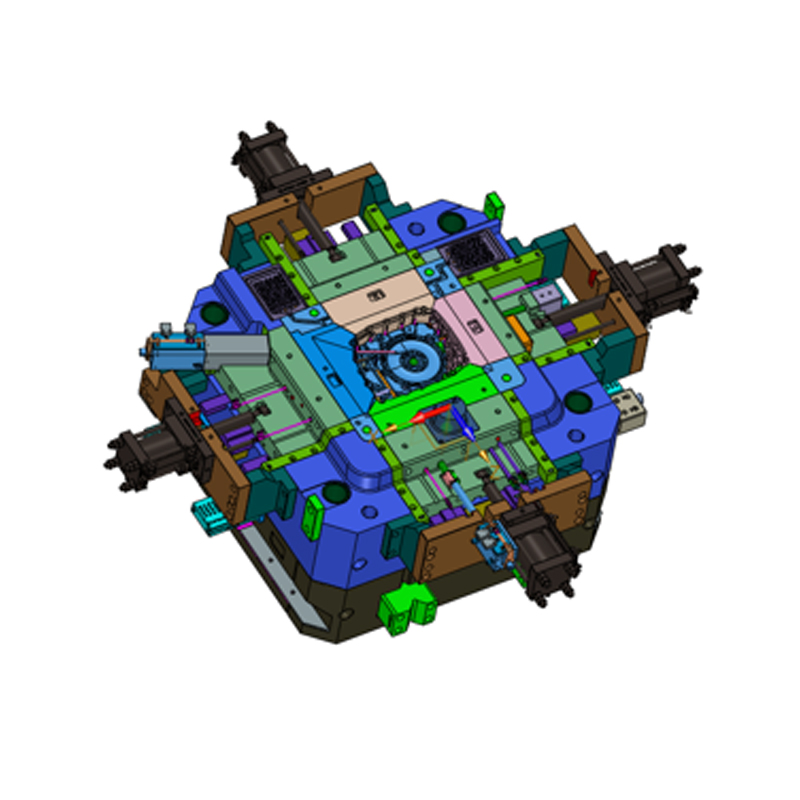

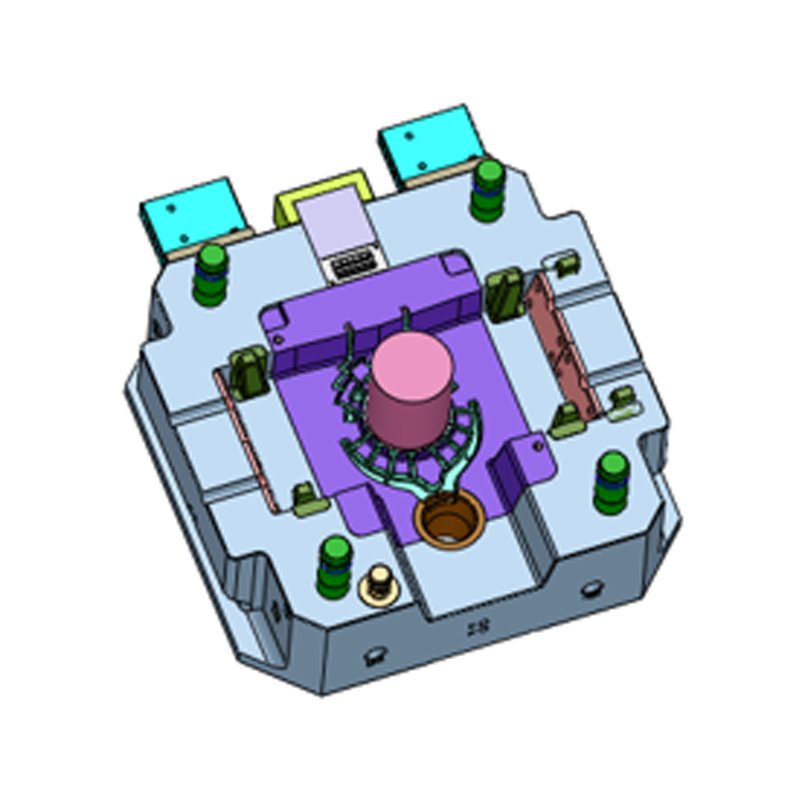

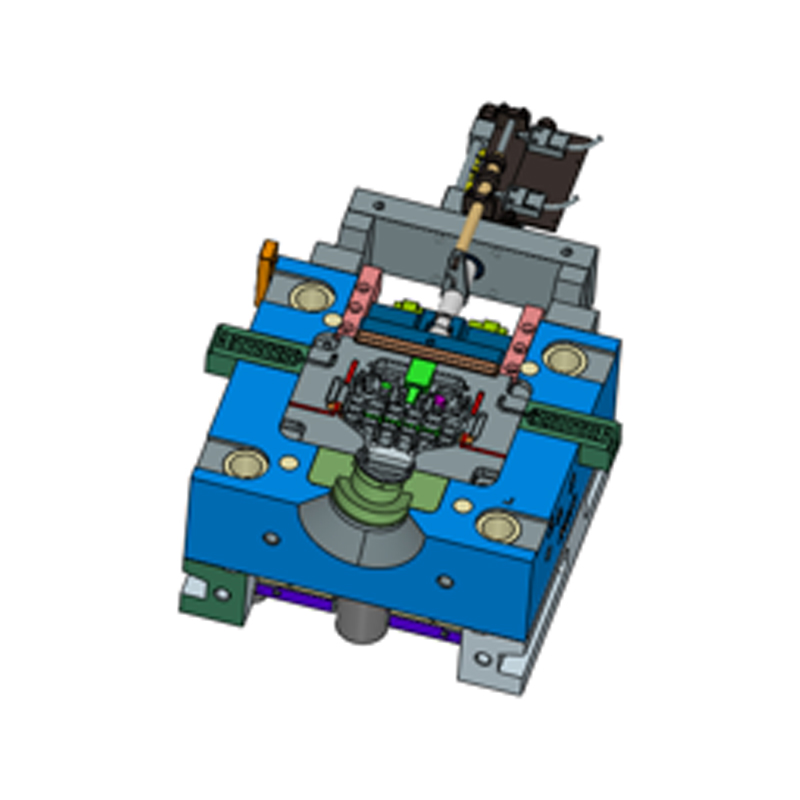

Different complexity of component structures

The three-electric system (battery, motor, and electronic control) components of new energy vehicles have complex structures, and the requirements for mold design accuracy are increased. For example, the battery shell usually adopts an integrated molding solution with thin wall thickness and fine structure. The mold needs to have a good cooling system and precise dimensional control capabilities. The molds for traditional vehicles in the manufacturing of metal parts such as engines and gearboxes pay more attention to high strength and thermal fatigue performance. There are differences between the two in the complexity of the mold cavity and the control of molding details.

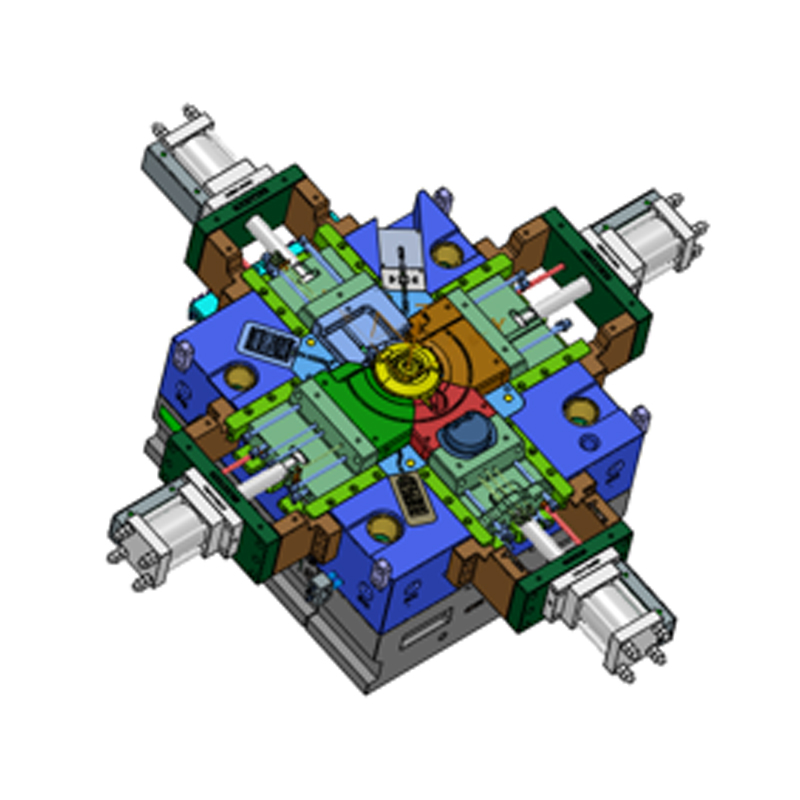

Differences in product size and integration

New energy vehicles have higher requirements for the integration of parts and components. For example, modular design of integrated electronic control boxes, motor housings and charging interfaces is becoming a trend. Such highly integrated parts are large in size and complex in structure, and casting molds need to have higher consistency control and multi-point feeding design. Traditional automotive molds usually serve split structural parts, with small single part sizes, relatively uniform mold load distribution, and relatively low difficulty in controlling thermal stress.

Challenges brought by thermal management systems

New energy vehicle parts (especially power batteries and motor housings) have clear requirements for thermal management. During the development process, the mold needs to consider whether a good heat dissipation structure design can be achieved after the product is formed, which directly affects the product performance. Traditional vehicle molds have less design pressure in this regard. For new energy products, mold development often integrates cooling channel design, casting cavity layout optimization, and thermal stress analysis methods.

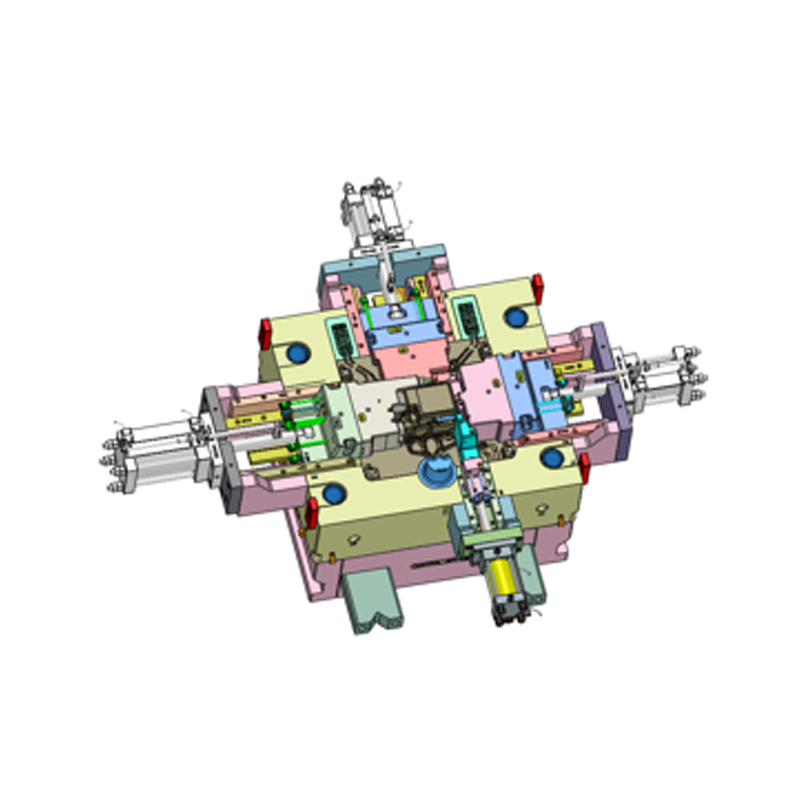

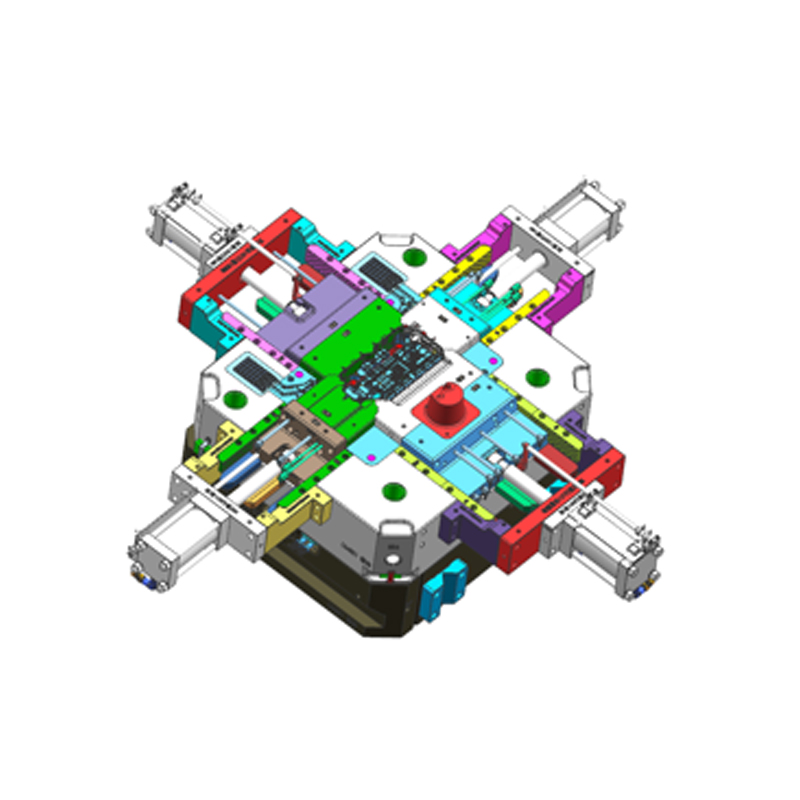

Differences between die-casting process and injection system

New energy vehicles often use high-pressure die-casting or vacuum die-casting processes, and the mold must adapt to the technical process of high-speed injection, high-pressure molding and rapid cooling. Under high-pressure conditions, the mold clamping force distribution, exhaust system and mold temperature control system are more critical. In contrast, ordinary low-pressure casting or gravity casting is still widely used in traditional vehicle molds, and the requirements for mold systems are slightly lower.

More stringent requirements for precision control

The requirements of new energy vehicles for safety and performance stability have prompted mold precision to approach the micron level, especially in battery module housings, electronic control housings, etc., and stricter standards are proposed for the dimensional tolerance, concentricity, and flatness of the mold. Although traditional automotive molds also focus on precision, the overall requirements are relatively loose, especially in some large structures, which allow a certain amount of post-processing space.

The mold life and maintenance methods are obviously different

Since new energy molds are often used in high-pressure casting and high-frequency production lines, mold life is challenged. Mold material selection, heat treatment process, and temperature control maintenance during mold use have become the focus. The maintenance rhythm of traditional vehicle molds is relatively stable, the processing environment is more controllable, and the management pressure of maintenance frequency and mold life is relatively low.

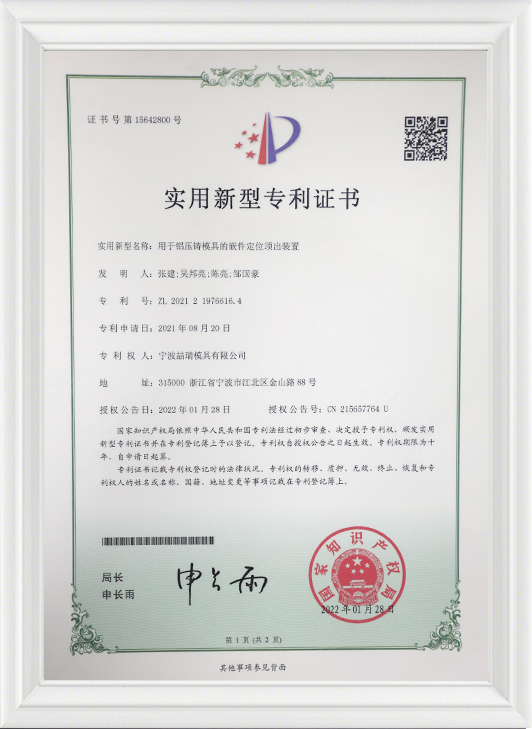

The application degree of design tools and simulation technology

In the design process of new energy vehicle casting molds, simulation analysis tools such as Moldflow and Magmasoft are widely used to help optimize gate layout, predict filling effect and shrinkage deformation. This digital design method significantly improves the efficiency and accuracy of mold development. Traditional mold design is still in the transition to digitalization, and its technology dependence is relatively low.

How does NKT Tooling ensure that the casting molds for the new energy vehicle series have good thermal management performance?

Importance of thermal management in new energy casting molds

New energy vehicle parts mostly use high-pressure die-casting or vacuum die-casting technology, and the distribution of thermal stress has a direct impact on the mold life and product molding quality. The mold must withstand the alternating effects of rapid heating and cooling during the casting process, so the thermal management capability determines the stability, cycle efficiency and molding consistency of the mold. Good thermal management design can control the temperature difference between various parts of the mold, reduce the risk of thermal fatigue cracking, and improve the production rhythm.

Material selection to meet heat conduction requirements

In order to improve the heat conduction efficiency of the mold, Ningbo NKT Tooling Co., Ltd. will select steel or alloy materials with higher thermal conductivity according to the part structure and casting method, such as H13 improved tool steel, 1.2343 ESR, 1.2367, etc., to enhance the mold body's ability to absorb and release heat. In addition, for areas that require key cooling, the company will also introduce copper alloy inserts or plugs to further balance the local temperature.

Refined design of built-in cooling channels

In terms of thermal management structure design, NKT Tooling uses 3D CAD software to simulate and analyze the layout of cooling channels to ensure that the cooling system covers the key molding areas of the mold. For example, in the battery shell or controller shell mold, a straight-through water channel, a spiral cooling circuit or an independent temperature control cavity will be designed to achieve rapid temperature dispersion and effective control. These channels are often completed by CNC deep hole drilling to improve processing accuracy and structural stability.

Thermal field simulation analysis improves predictive ability

The company widely uses thermal simulation software such as MAGMASOFT or ProCAST to dynamically analyze the heat conduction, heat concentration and cooling rate of the mold during the die-casting process. By predicting and adjusting the thermal changes in each stage, the thermal control blind spots or hot spots are corrected in advance, the uniformity of the mold thermal cycle is improved, and deformation or stress concentration is avoided. The impact on the size of the part.

Integrated management of temperature control system

In order to facilitate actual operation and monitoring, Ningbo NKT Tooling Co., Ltd. can equip the mold with an integrated temperature control system that supports functions such as mold temperature machine connection, thermocouple monitoring, and regional temperature adjustment. Through systematic management of thermal parameters, users can adjust the mold temperature curve under different production conditions to maintain a stable molding state. This integrated design is particularly suitable for molds such as high-demand electric drive housings and new energy control unit housings.

Multi-material combination reduces thermal fatigue risk

For high-frequency thermal shock areas, such as gates, venting grooves or thin-wall transition areas, NKT Tooling will use a combination of multiple materials. For example, materials with different thermal expansion coefficients are embedded in high-temperature flushing positions to improve thermal shock absorption and reduce cracking and edge collapse. This local material optimization strategy effectively extends the overall service life of the mold.

Maintenance and feedback mechanisms help optimize thermal performance

After the mold is delivered for use, the company will also provide regular inspection and thermal performance evaluation services based on customer usage. By analyzing the flowability of the cooling system, temperature difference reaction time, and surface thermal fatigue traces, improvement suggestions are provided for the subsequent use of the mold or the development of new molds. This full-process thermal management support mechanism provides a basis for the stable operation and continuous optimization of the mold.

English

English 中文简体

中文简体