What is a zinc alloy die-casting mold and what are its typical application areas?

Basic definition of zinc alloy die-casting mold

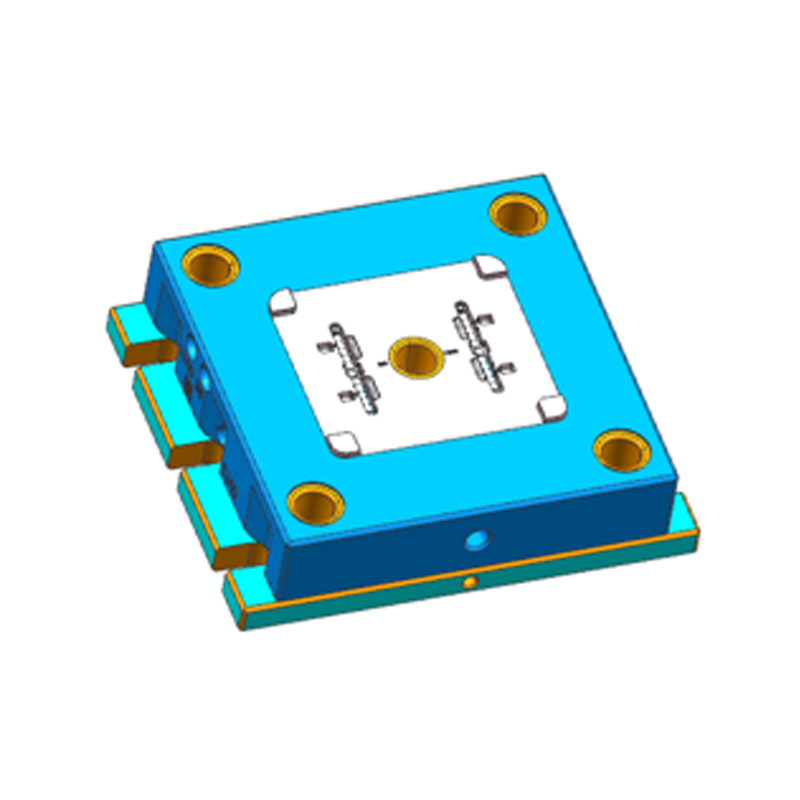

Zinc alloy die-casting mold is an industrial mold specially used for die-casting of zinc alloy materials, which is widely used in high-efficiency batch manufacturing of small and medium-sized metal parts. It injects molten zinc alloy into a high-strength mold cavity through the die-casting process, quickly cools and solidifies to obtain metal products with complex structures, fine contours and relatively high dimensional accuracy. Zinc alloy occupies an important position in die-casting manufacturing due to its excellent casting performance and easy processing characteristics.

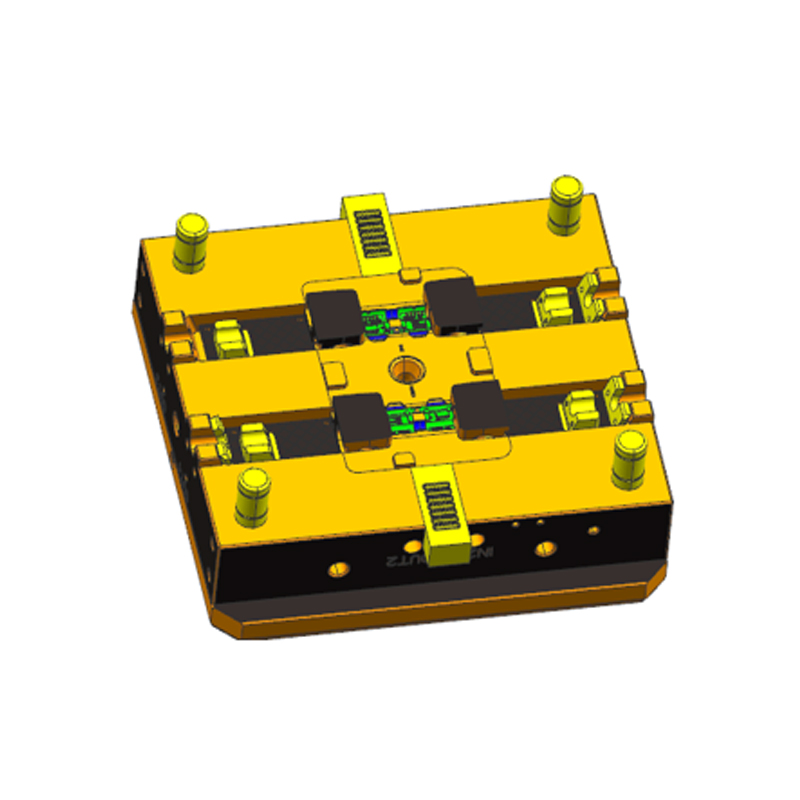

Zinc alloy molds are usually made of steel. When designing, factors such as product structure, cooling system, exhaust channel, parting line, etc. should be considered. The service life, heat resistance and surface treatment of the mold will directly affect its production efficiency and the quality performance of the die-casting.

Positioning of Ningbo NKT Tooling Co., Ltd. in zinc alloy mold manufacturing

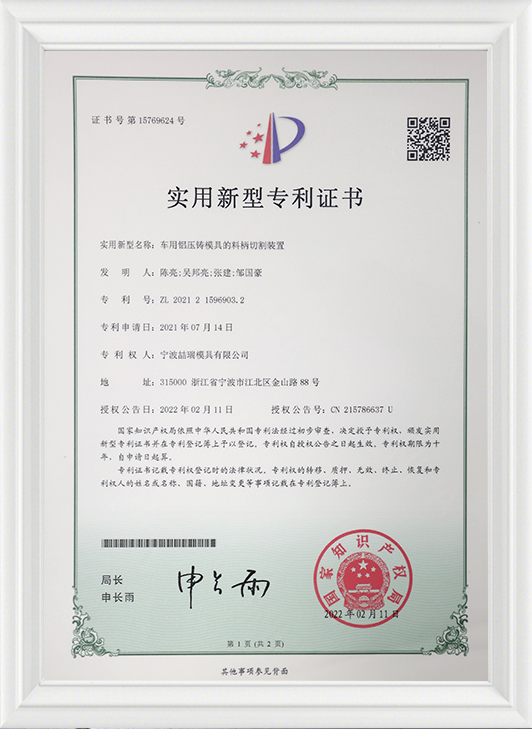

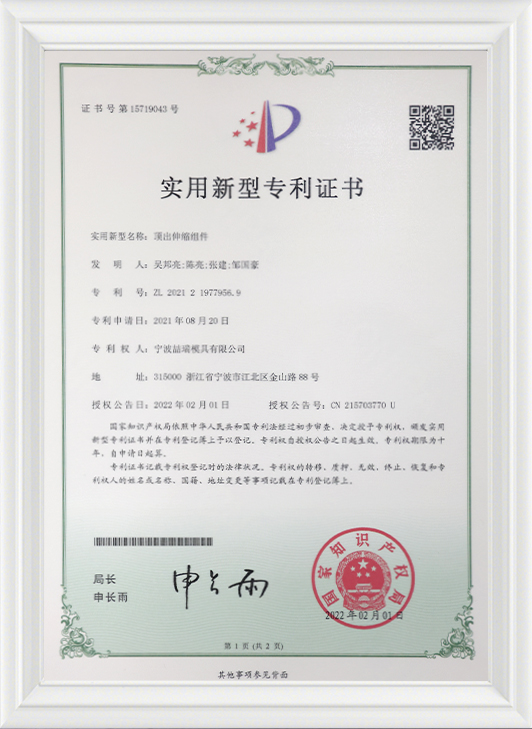

Since its establishment in 2009, Ningbo NKT Tooling Co., Ltd. has focused on the research and development and manufacturing of aluminum, magnesium and zinc alloy die-casting molds. Relying on advanced processing equipment, professional technicians and systematic manufacturing processes, the company has the ability to produce more than 300 sets of high-precision molds annually. As an important part of its product line, zinc alloy molds are widely used in industries such as automobiles, electronics, electrical appliances, hardware and consumer goods.

The company combines the application needs of various industries to provide mold solutions with reasonable structure and stable molding, helping customers improve product consistency and production efficiency.

Main advantages and characteristics of zinc alloy die-casting molds

Zinc alloy die-casting molds have the following performance characteristics, making them widely applicable in the manufacturing of small and medium-sized parts:

High-precision casting ability: zinc alloy has good fluidity and is suitable for casting complex and detailed structures;

Short molding cycle: the mold structure is reasonably designed, which is conducive to rapid molding and demolding, and improves production efficiency;

Long mold life: due to the low melting point of zinc alloy, the heat load on the mold is small, which helps to extend the mold life cycle;

Good product surface quality: the surface finish of the die-casting is high, which is suitable for later surface treatment processes such as electroplating and painting;

Strong economy: suitable for large-scale continuous production, saving labor and material costs.

These characteristics make zinc alloy die-casting molds have practical advantages in manufacturing cycle, molding stability and surface treatment.

Typical application areas of zinc alloy die-casting molds

Zinc alloy die-casting molds are used in multiple industrial and consumer fields. The following are some typical industries and application scenarios:

Automotive industry: used to manufacture precision parts such as door handles, air-conditioning outlet frames, interior brackets, small shafts, etc. Such parts usually have strict requirements on structural dimensions and require mass production.

Electronic appliances: used to manufacture socket panels, terminal blocks, computer accessories, heat dissipation shells and other products. Zinc alloy die-casting can ensure the dimensional accuracy and installation consistency of electronic accessories.

Communication equipment: used to manufacture small and medium-sized parts such as mobile phone cases, signal equipment protective shells, optical fiber connectors, etc., to meet the needs of equipment lightweight and electromagnetic interference shielding.

Household appliances and kitchen and bathroom hardware: such as mixer accessories, faucet joints, lamp brackets, lock parts, etc. These products require the mold to have a certain complex structure and good demolding properties.

Tools and hardware products: such as hand tool handles, measuring instrument shells, process accessories, etc., zinc alloy molds can ensure consistent shape and stable mechanical properties.

Consumer product shells: such as luggage locks, glasses holders, small decorative parts, etc., pursuing beautiful appearance and mass production capabilities.

What factors affect the molding accuracy of zinc alloy die-casting molds?

Influence of material properties on molding accuracy

The physical properties of zinc alloy itself play a fundamental role in the molding accuracy of molds. Zinc alloy has a low melting point, strong fluidity, and fast solidification speed, but its thermal expansion coefficient is high, and it is easy to shrink and deform during the cooling process. If the dimensional changes of the material during the flow, cooling and solidification process are not fully considered, it is easy to cause dimensional deviations in the die casting. In the early stage of zinc alloy die-casting mold design, it is necessary to fully understand the thermodynamic properties of zinc alloys and make appropriate compensation designs for the molding cavity to reduce errors.

Rationality of mold structure design

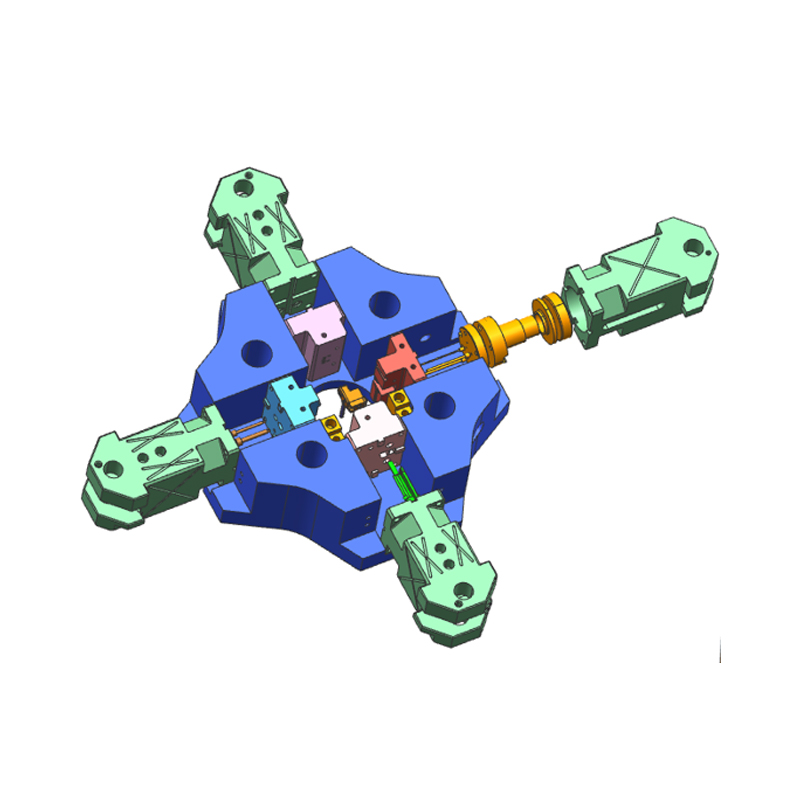

The mold structure directly determines the geometric accuracy and surface consistency of the molded part. If the mold parting line is set unreasonably, it is easy to cause dislocation at the product formation point; if the exhaust system is insufficient, the air cannot be discharged smoothly, which will cause defects such as pores and cold shuts, thereby affecting the dimensional accuracy and the overall appearance of the product. The design of the mold cooling system is also very critical. Insufficient local cooling may cause local shrinkage deformation. Therefore, Ningbo NKT Tooling Co., Ltd. often conducts multiple rounds of simulation analysis and adjustments on complex products during the mold design stage, striving to ensure that the mold structure is stable during the die casting process.

The influence of machining accuracy on mold forming effect

The machining accuracy of the mold body is the key link to ensure the dimensional stability of the die casting. If there is a slight error in the mold cavity, guide system or core, it will be directly reflected in the product. Especially in multi-cavity molds, the machining error of each cavity will affect the consistency of the product. For this reason, Ningbo NKT Tooling Co., Ltd. uses high-precision CNC machining equipment (such as five-axis linkage machine tools, EDM, coordinate grinders, etc.) to control the machining error of key parts of the mold, usually within ±0.01mm.

Matchability of die-casting process parameters

The process parameter setting in the die-casting process also directly affects the final molding accuracy. Such as melt temperature, mold temperature, injection speed, pressurization time, etc., all need to be reasonably adjusted according to the specific product and mold structure. Too high temperature may cause burrs and deformation, too low temperature may easily cause insufficient filling, affecting the integrity of the molding; and too fast injection system speed will cause flash, erosion and other problems. Therefore, before mass production, it is usually necessary to conduct multiple process trials to obtain a suitable parameter combination.

Mold wear and maintenance status

During long-term use, the mold will be affected by factors such as thermal fatigue, wear and corrosion, which will lead to microscopic changes in the cavity surface and affect the consistency of product size. For example, the wear of the rounded corners of the cavity edges will cause problems such as uneven chamfers and offset of positioning holes. Therefore, regular inspection and maintenance of the mold is an indispensable measure to maintain molding accuracy. Ningbo NKT Tooling Co., Ltd. cleans, inspects and records the mold after each production batch to ensure that the mold maintains a relatively stable operating state during its life cycle.

Operation accuracy of mold clamping equipment

When the mold is installed on the die-casting machine, the accuracy of the equipment itself will also affect the size of the molded part. Including uneven clamping force, template deformation, loose guide pillars and other problems, all of which may cause the mold to shift during the clamping process, causing deformation or error in the product. Especially for zinc alloy parts with thin wall thickness and high dimensional requirements, die-casting equipment with high clamping accuracy is more required to be used with the mold.

Process execution level of operators

Molding accuracy not only depends on the equipment and mold itself, but also is closely related to the process execution ability of the operator. Fluctuations in raw material properties, changes in ambient temperature, and adjustments to human parameters in different batches can cause inconsistencies in product molding accuracy. Therefore, Ningbo NKT Tooling Co., Ltd. is equipped with experienced mold operators and reduces the impact of human factors on mold accuracy through standardized process documents and process management.

Finished product inspection feedback and optimization closed loop

During the die-casting production process, the finished product inspection link can promptly discover and feedback accuracy deviation problems. Through precision inspection equipment such as three-coordinate measuring machines and projectors, a comprehensive assessment of the key dimensions and form and position tolerances of die-casting parts can assist engineers in tracing the source of the problem and adjusting the mold or process parameters. Ningbo NKT Tooling Co., Ltd. has established a standardized quality tracking system to achieve full process monitoring from mold development, mold trial to mass production, and effectively control molding accuracy.

English

English 中文简体

中文简体