What are the common design characteristics of conventional vehicle series die casting molds?

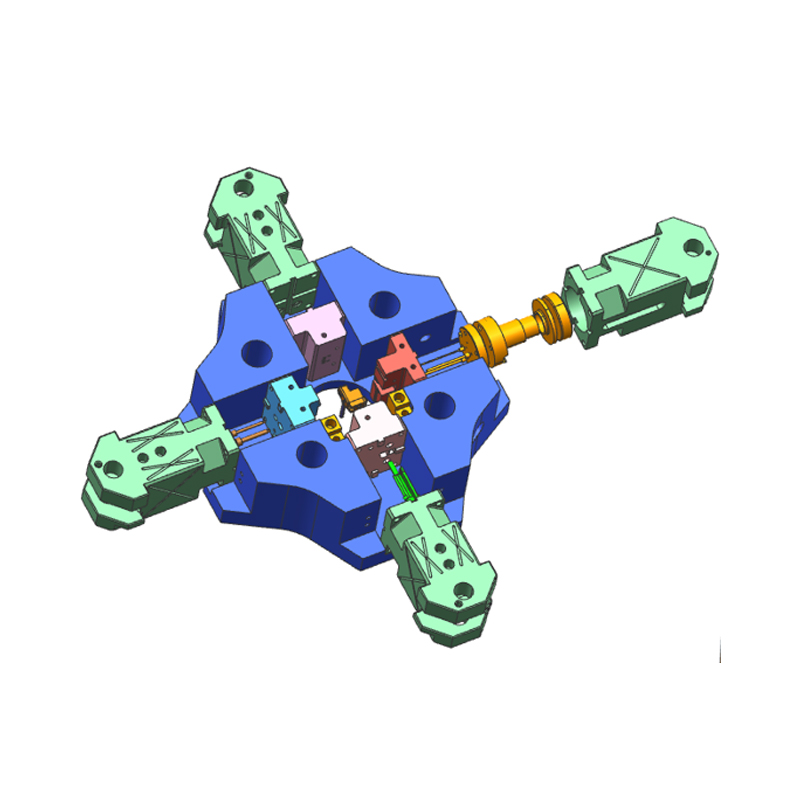

Highly targeted design

The design of conventional vehicle series die casting molds is usually centered around the specific vehicle model and its components requirements. Ningbo NKT Tooling Co., Ltd. will gain an in-depth understanding of the functions, structure and installation environment of vehicle components during the design process to ensure that the mold can accurately match the size and performance requirements of the final product. This targeted design helps improve the machining efficiency and assembly accuracy of castings.

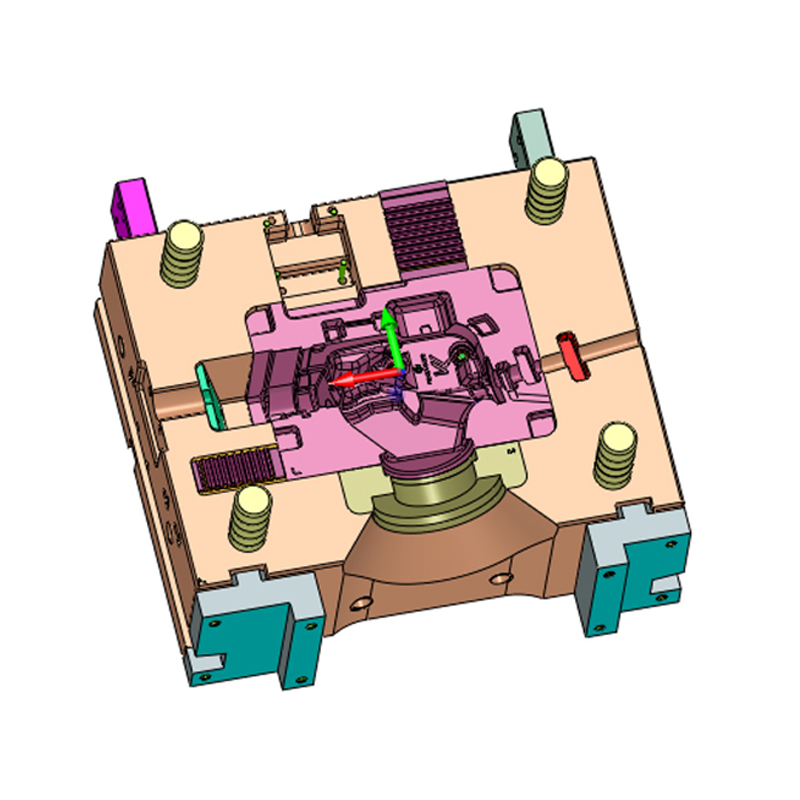

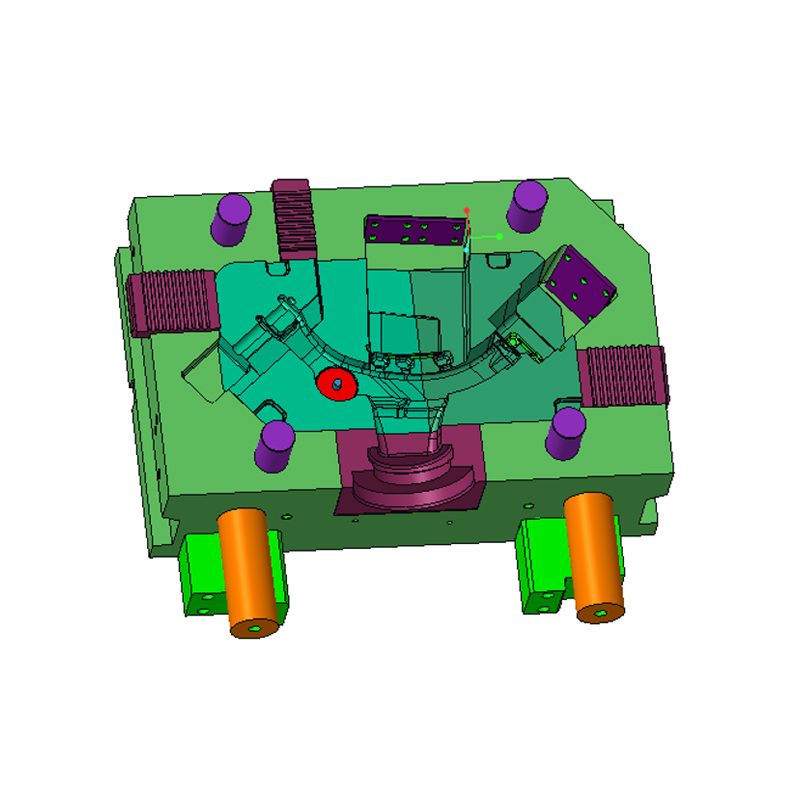

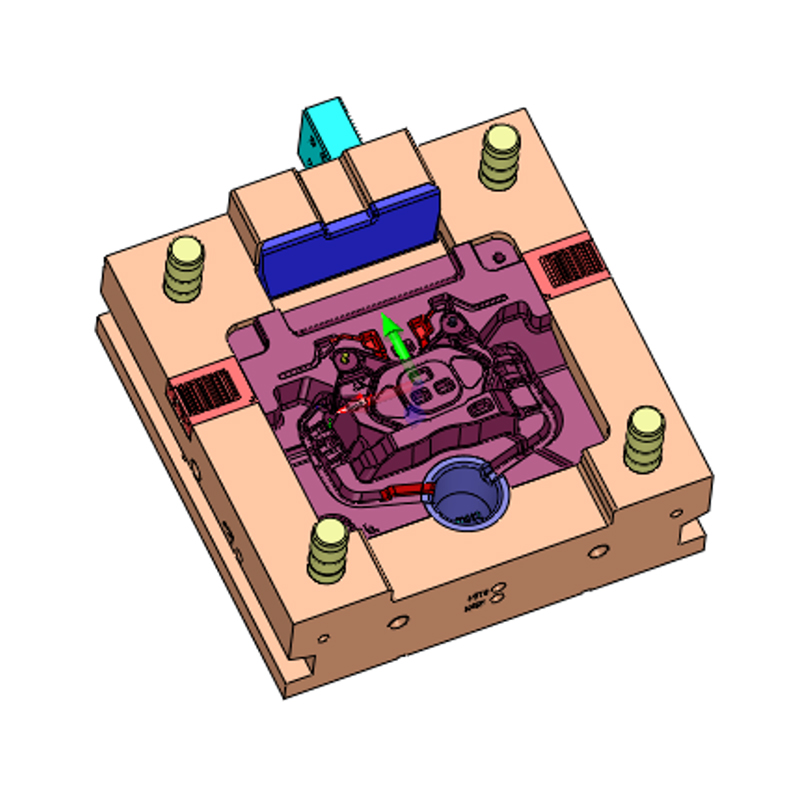

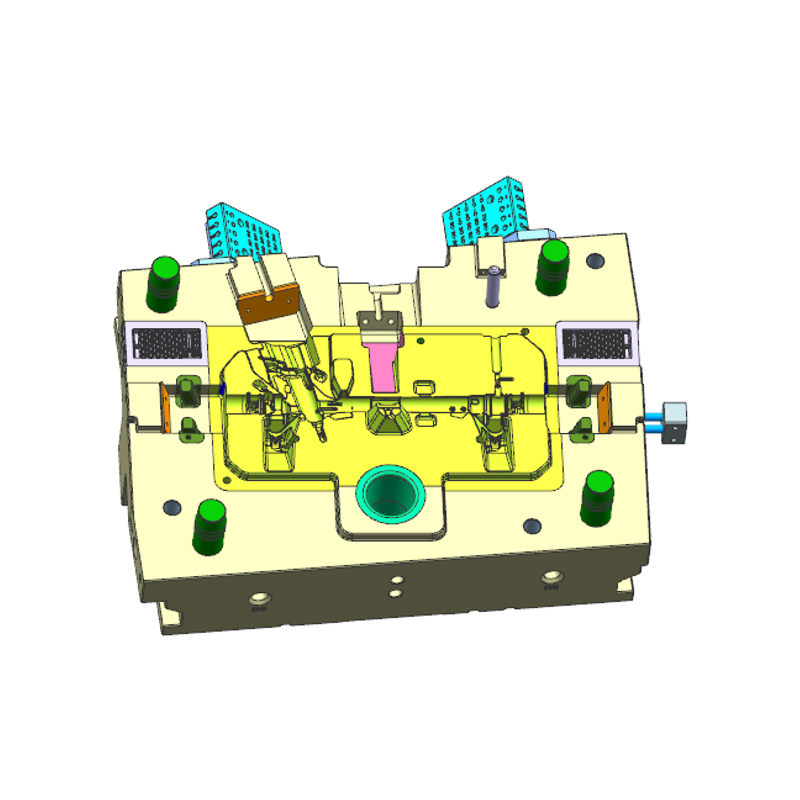

Complex but reasonable structure

Vehicle cast parts are usually complex in shape and involve multiple functional surfaces and connecting structures. Therefore, mold design needs to consider the rationality of the overall structure. Designers need to take into account the rigidity, exhaust, cooling and demolding properties of the mold to ensure that the mold can operate stably during the production process, avoid deformation and damage, and ensure the quality of the castings.

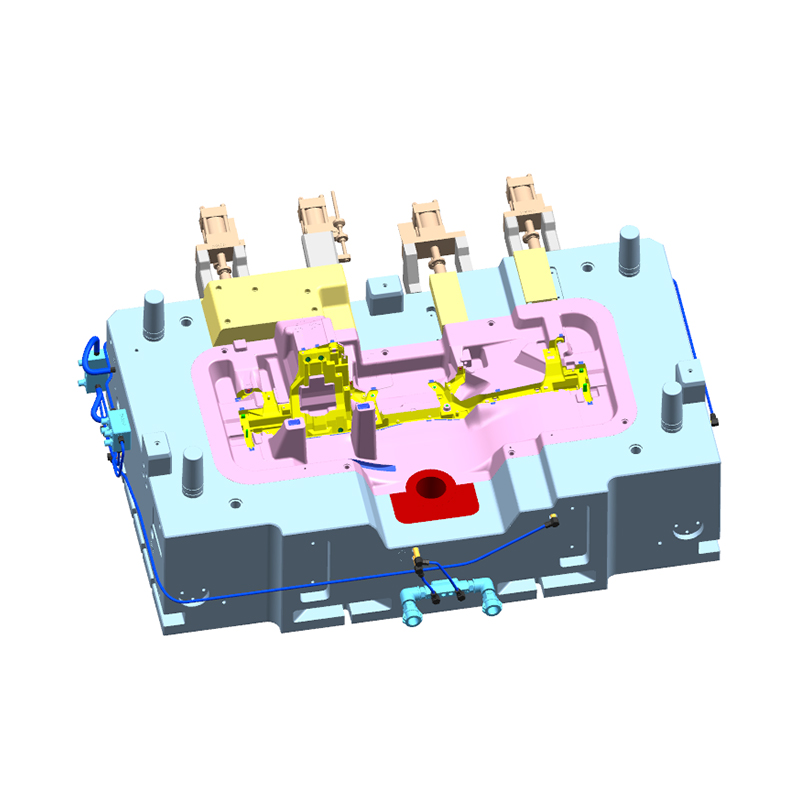

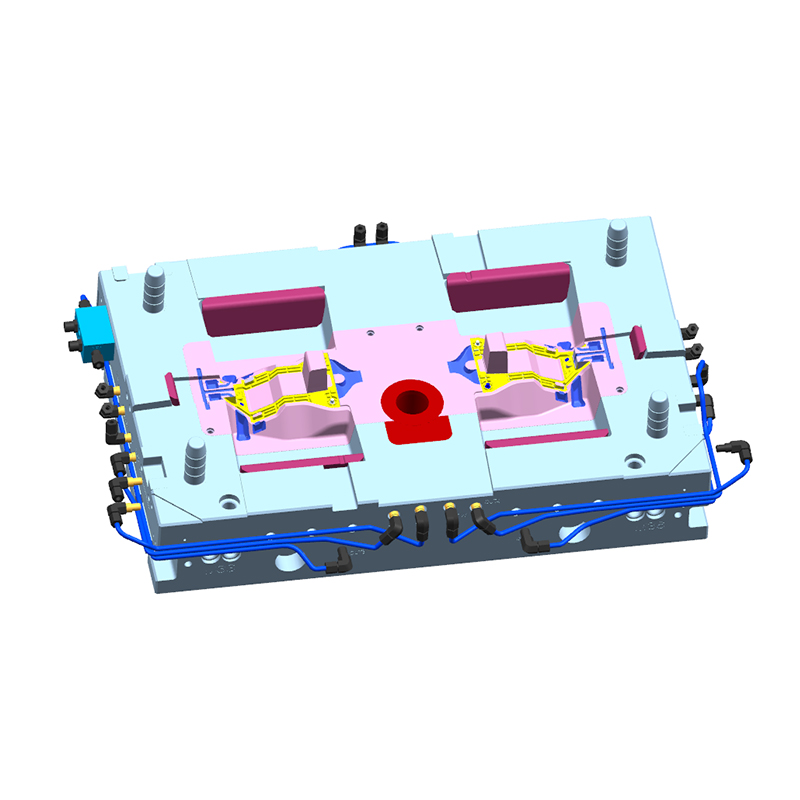

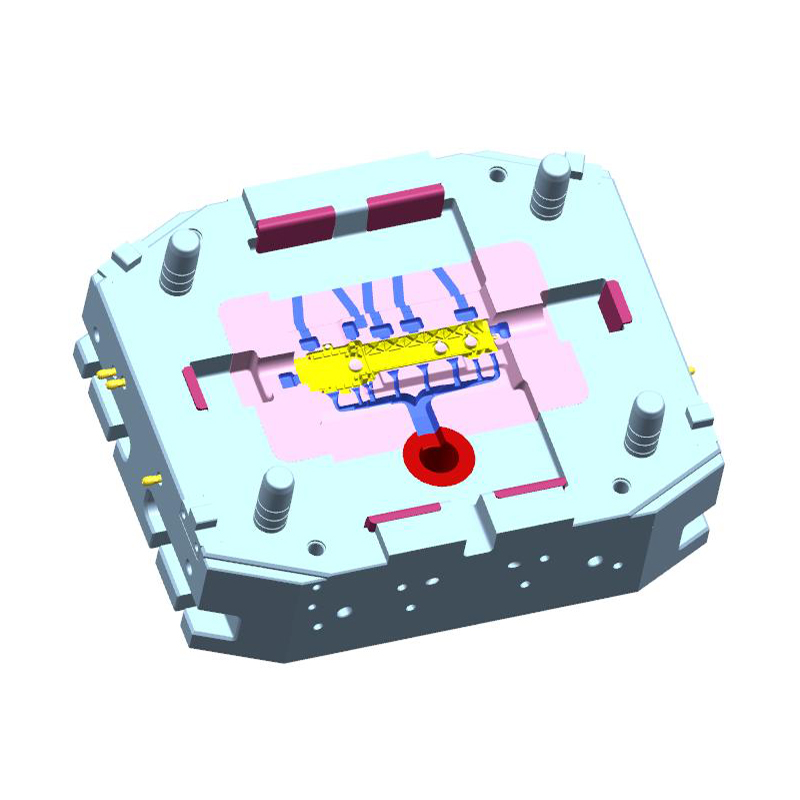

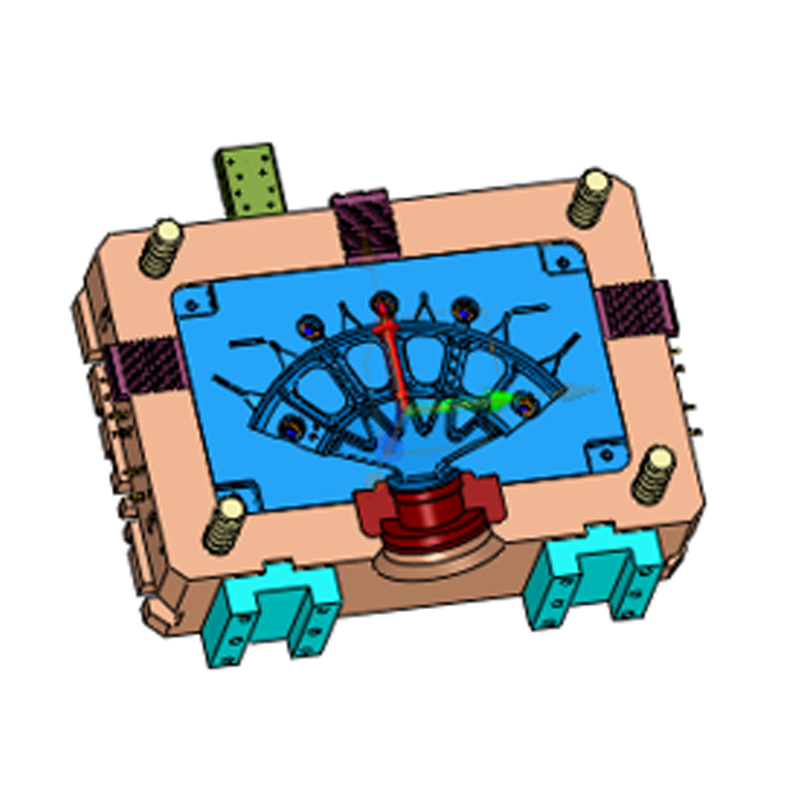

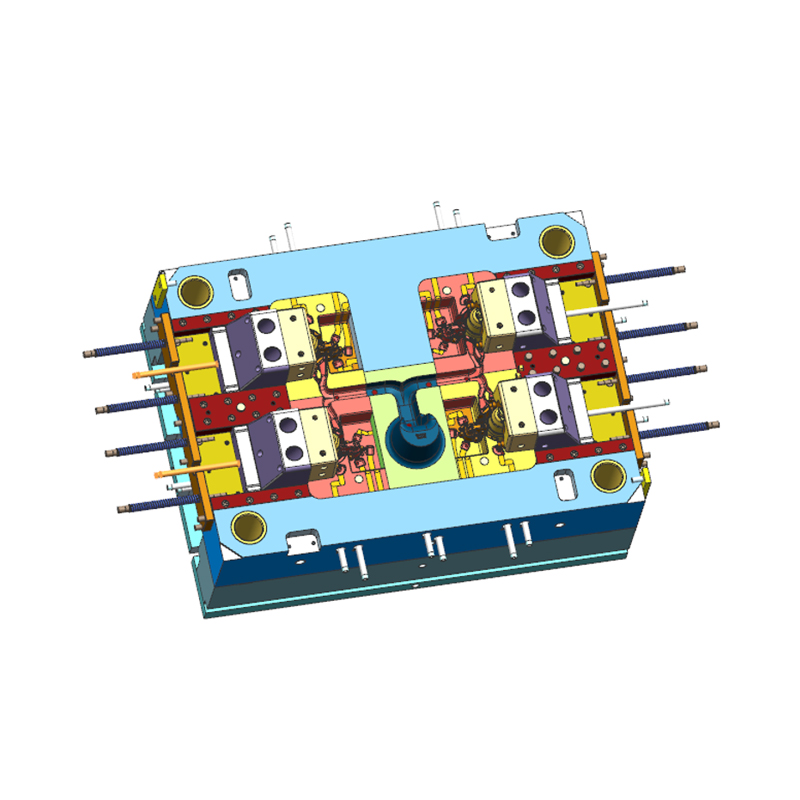

Adopt a split model design

conventional vehicle series die casting molds mostly adopt a mold split design, that is, the mold is divided into multiple parts for easy assembly and replacement. The split mold design not only improves the flexibility of the mold, but also facilitates daily maintenance and repairs, while helping to improve production efficiency and reduce production downtime.

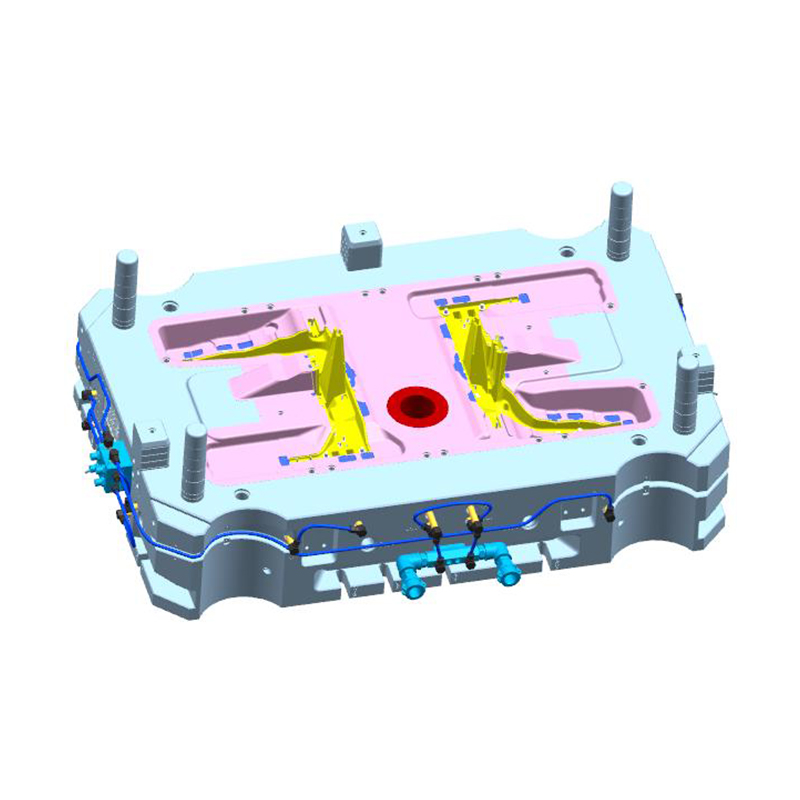

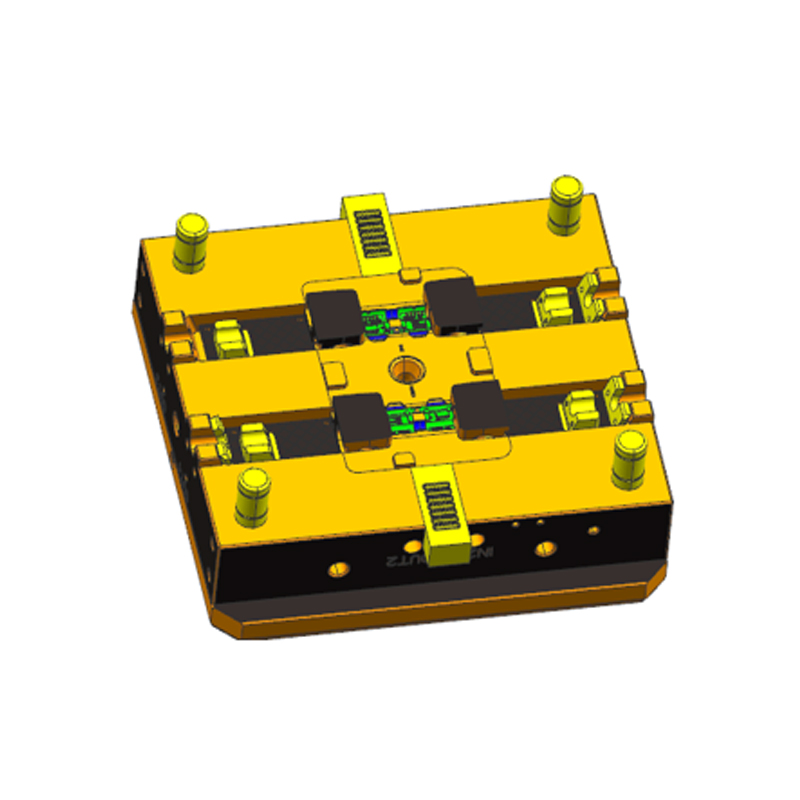

Pay attention to cooling system layout

The design of mold cooling system is the key to ensuring casting quality and mold life. Ningbo NKT Tooling Co., Ltd. focuses on the reasonable layout of cooling channels to quickly and effectively dissipate heat, reduce thermal stress of castings, prevent overheating and deformation of the mold, and extend the service life of the mold.

Taking into account material properties and processing technology

The characteristics and casting process requirements of the alloy materials used (such as aluminum, magnesium, zinc alloys) and the design should be fully considered. The thermal expansion coefficient, fluidity and solidification characteristics of different materials are different. The mold design needs to adjust the size and structure accordingly to ensure the dimensional stability and surface quality of the castings.

Design with emphasis on mold durability

Vehicle casting molds face a large number of production tasks, and the design focuses on improving wear resistance and fatigue resistance. Ningbo NKT Tooling Co., Ltd. selects suitable steel and surface treatment processes in the design to strengthen easily worn parts and ensure that the mold maintains stable performance during long-term operation.

Take into account both processing and assembly convenience

The mold design also needs to consider the convenience of manufacturing and post-assembly, reasonably arrange the processing sequence and assembly method of each mold component to reduce production difficulty and cost. This design idea helps shorten production cycles and improve delivery efficiency.

Focus on precision control

conventional vehicle series die casting molds have high requirements for dimensional accuracy. The design will combine advanced measurement technology and process parameters to ensure mold manufacturing accuracy and assembly accuracy, thereby meeting the strict quality standards of vehicle parts.

Adapt to mass production needs

Vehicle parts usually require mass production, and mold design needs to meet the requirements of long-term high-strength use. Ningbo NKT Tooling Co., Ltd. fully considers durability and maintenance convenience during design, making the mold suitable for mass production and ensures production continuity.

Integrate customer customization needs

During the design process of conventional vehicle series die casting molds, Ningbo NKT Tooling Co., Ltd. attaches importance to customers' special requirements and provides personalized design solutions to meet the special process and technical needs of different models and different parts, and improve customer satisfaction.

What measures have conventional vehicle series die casting molds taken in precision control?

Precision design software supports mold accuracy control

During the design stage of conventional vehicle series die casting molds, Ningbo NKT Tooling Co., Ltd. widely uses three-dimensional modeling software and computer-aided design systems (such as UG, CATIA, and Pro/E) to digitally model the mold structure. These tools help engineers to carefully control the dimensions, coordination tolerances and assembly relationships of parts at the beginning of design to ensure controllable design accuracy. Through preliminary simulation analysis, the material flow path, temperature field and stress concentration area can also be optimized to improve the accuracy basis for subsequent mold manufacturing and use.

Strictly control mold processing tolerances

The machining accuracy of the mold directly affects the quality of the final casting. Ningbo NKT Tooling Co., Ltd. uses high-precision CNC machine tools, five-axis machining centers, wire cutting equipment and electric spark machining technology in the mold manufacturing process to implement micron-level tolerance control for key locations. At the same time, technicians have refined the management of tool wear, feed speed, spindle speed and other parameters to ensure that each processing step is within the standard range and reduce dimensional deviation.

Manufacture of molds using high stability materials

The dimensional stability of the material is the basic condition for controlling accuracy. Ningbo NKT Tooling Co., Ltd. prefers mold steel materials with strong thermal stability and wear resistance (such as H13, SKD61, etc.). These materials are not easily deformed after repeated high-temperature casting, which helps maintain the dimensional accuracy of the mold for a long time. In addition, during the steel heat treatment process, the company adopts a multi-stage temperature control process to reduce the internal stress of the material and reduce errors caused by thermal deformation.

Multi-round inspection system improves accuracy guarantee

To ensure that the mold accuracy meets the design requirements, Ningbo NKT Tooling Co., Ltd. implements a full-process testing system. Starting from the rough processing stage of parts, dimensional inspection is carried out, and comprehensive measurements are carried out on each key part after finishing. Use three-coordinate measuring instruments (CMM), altimeter, optical projector and other detection tools to obtain high-precision dimensional data. All measurement results are compared with CAD data. Parts with deviations exceeding the preset range will be reprocessed or scrapped to ensure the accuracy of the mold assembly.

Verify accuracy and stability in mold test process

After the mold is completed and assembled, Ningbo NKT Tooling Co., Ltd. will conduct a mold test operation. By injecting actual alloy materials, the size, surface quality, thickness consistency of the trial products are comprehensively tested. The mold test results not only verify the dimensional control of the mold body, but also check whether there are factors that affect the accuracy of the cooling system, exhaust design and feeding system. The test mold feedback results are used to further debug the mold to achieve a stable state before mass production.

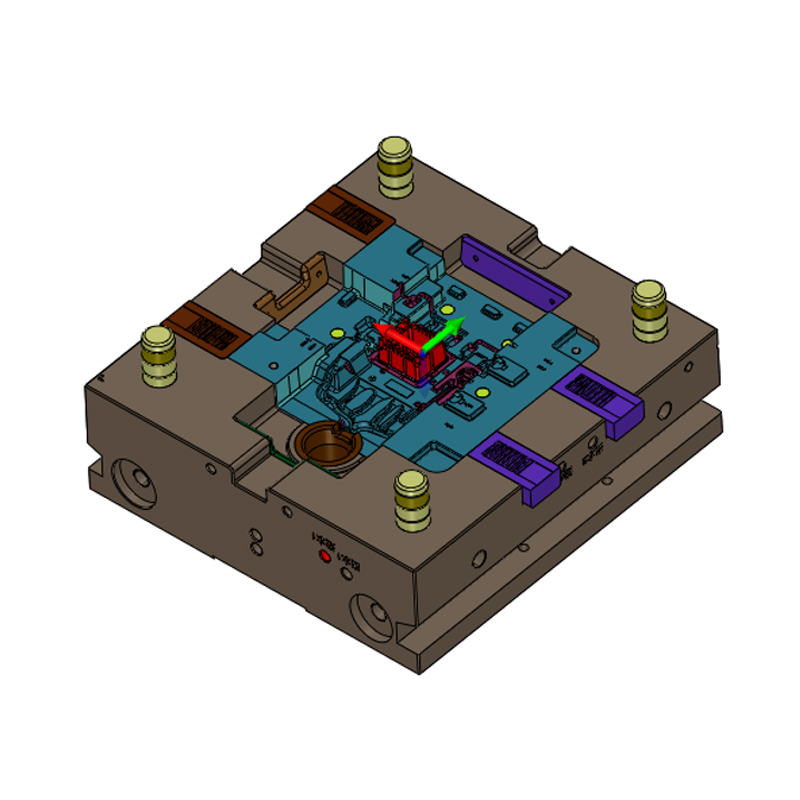

Temperature control system assists stable dimensional accuracy

During the die casting process, the mold is subjected to repeated high-temperature thermal shock, which challenges the mold dimensional stability. Ningbo NKT Tooling Co., Ltd. arranges a reasonable temperature control system in the mold, including cooling waterways and local temperature control devices to maintain the temperature balance in each area of the mold. Controlling the change amplitude of the mold thermal expansion and heat shrinkage helps maintain the accuracy of the molding cavity and reduces dimensional errors caused by temperature difference.

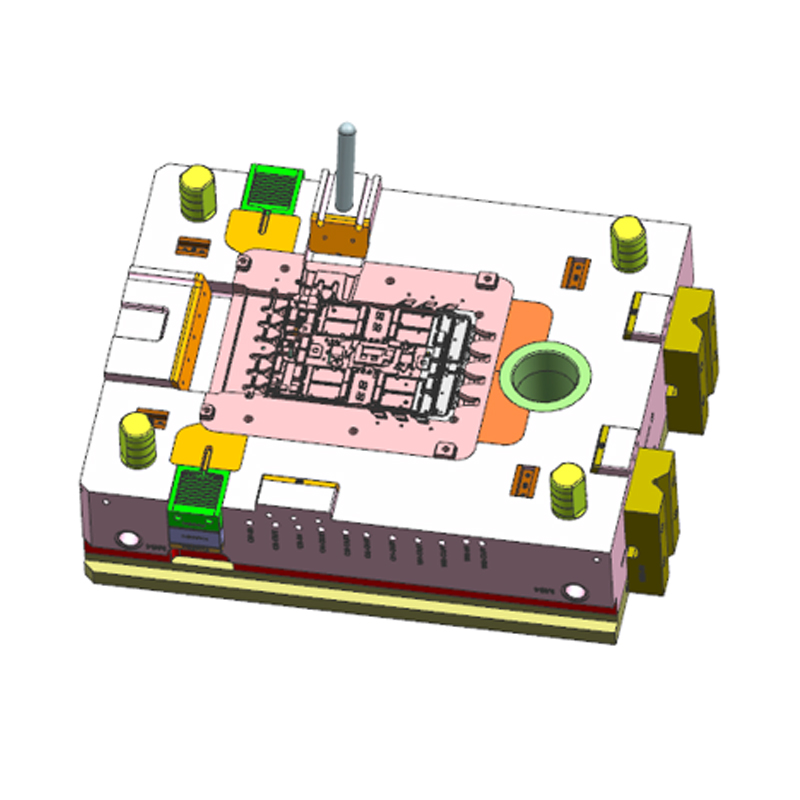

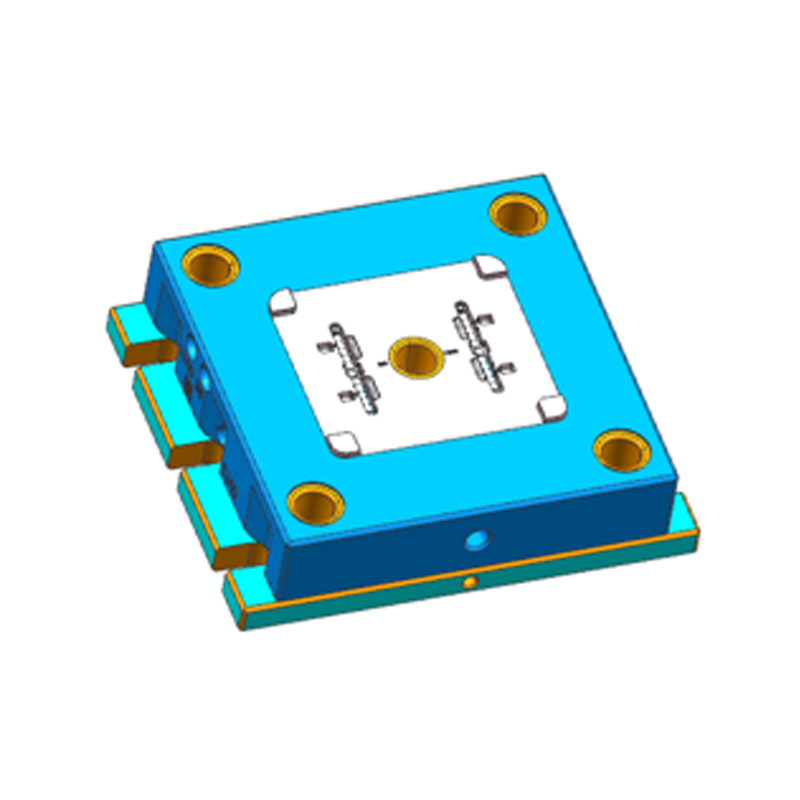

Modular and adjustable design of key components

In conventional vehicle series die casting molds, some key structures such as sliders, cores, inlays and other components are designed in modular or adjustable forms. Ningbo NKT Tooling Co., Ltd. adopts this method, without the need to replace the mold body as a whole during post-adjustment or repair. Only fine-tuning can achieve repair and control of local accuracy. This not only extends the service life of the mold, but also improves the efficiency of maintaining dimensional accuracy.

Personnel technical training and quality responsibility system

The production of high-precision molds depends on the skill level of the operator. Ningbo NKT Tooling Co., Ltd. regularly conducts professional training for technical workers and inspectors, including drawing reading, dimensional tolerance understanding, equipment operation specifications, etc. Establish a clear quality responsibility system and implement the accuracy control tasks to people. Each participant is responsible for its operational links and improve the accuracy management level of the entire process.

Data management and traceability system

Ningbo NKT Tooling Co., Ltd. has established a complete mold data recording system covering design parameters, processing data, test results and test feedback. Each set of molds has independent numbers and archives, which realizes traceable management of the entire process. Through the comparison and analysis of the data, potential sources of accuracy deviation can be discovered and corrected, which helps to continuously improve and quality tracking.

English

English 中文简体

中文简体