What are the technical differences between motor die-casting molds and ordinary die-casting molds?

Differences in applicable component types

Motor die-casting molds are mainly used for the molding of motor housings, end covers, rotors and other structural parts, which have higher requirements for dimensional accuracy, heat dissipation structure, coaxiality, etc. In contrast, ordinary die-casting molds correspond to a wider range of products, such as lamp housings, hardware accessories, home appliance parts, etc., with relatively scattered functional requirements and technical difficulties.

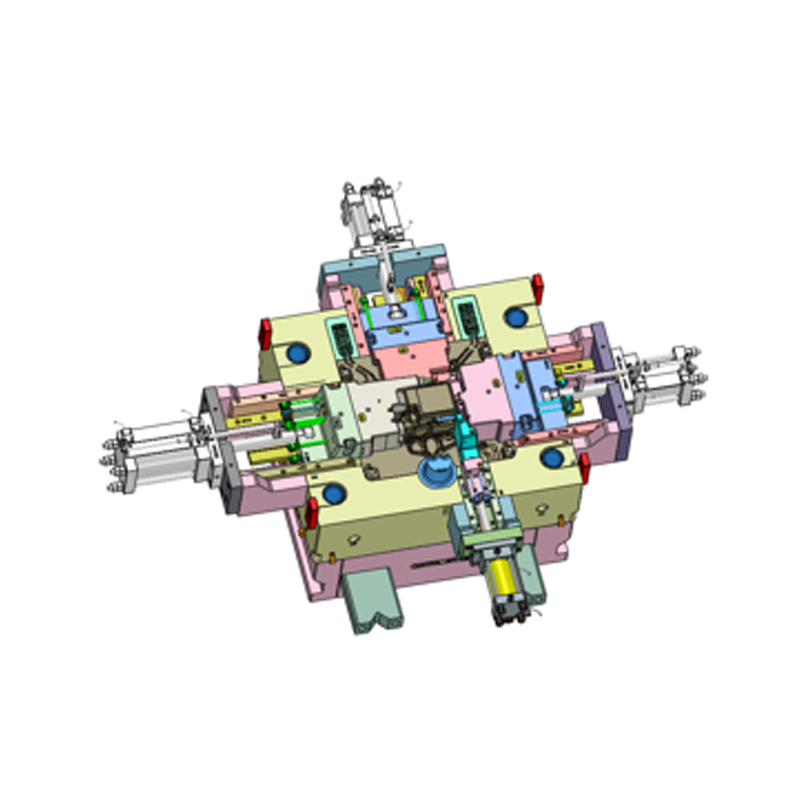

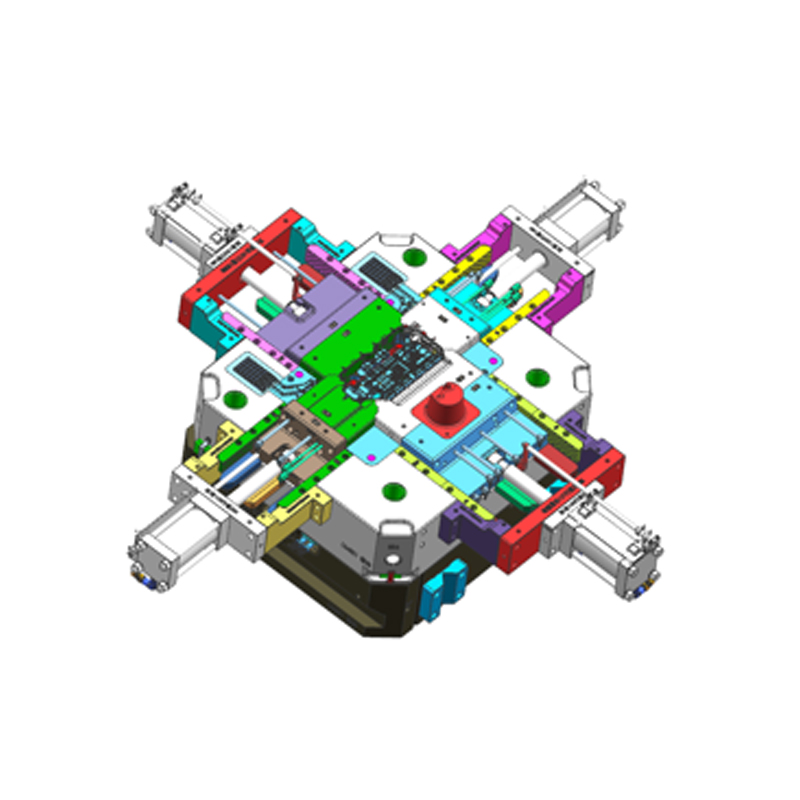

Differences in mold design structure

Ningbo NKT Tooling Co., Ltd. pays more attention to the symmetry of the mold cavity, the accuracy of the parting surface and the concentricity control of the mold in the design of motor die-casting molds to meet the dynamic balance requirements during motor operation. In the structural design of ordinary die-casting molds, more general parameters such as the feasibility of shape molding and demolding efficiency are considered. Some complex structures use active core pulling, and the technical tolerance is larger.

Differences in thermal management design

Motor molds usually integrate multiple sets of cooling channels to ensure temperature control of key parts of die-casting parts. Since the motor housing is mostly a thick wall structure, uneven heat distribution can easily cause internal shrinkage and deformation. Therefore, Ningbo NKT Tooling Co., Ltd. will optimize the cooling layout according to the thermal field simulation. Most ordinary die-casting molds are relatively simple in heat dissipation design, mainly based on basic cooling circuits, and the threshold of thermal control technology is relatively low.

Mold accuracy and stability requirements

Motor die-casting molds have very strict control over the post-processing allowance of the product, because the assembly of the motor needs to ensure the tightness of the housing and the stator and rotor. The mold must have high repeatability to avoid dimensional drift between batches. Although ordinary die-casting molds have requirements for dimensional consistency, they do not focus on the extreme control of features such as housing thickness difference and inner cavity roundness as motors.

Differences in adaptability of alloy materials

Ningbo NKT Tooling Co., Ltd. often involves high-strength aluminum alloy or magnesium alloy die-casting in motor mold design. These materials have high molding temperatures, and the molds need to have good thermal fatigue performance and corrosion resistance. In contrast, ordinary die-casting molds have a wider range of uses, and low-pressure materials such as zinc alloys and low-temperature aluminum alloys are also more common, and the requirements for mold materials are relatively loose.

Different service life and maintenance strategies

Since the products used in motor die-casting molds often need to be produced in large quantities, the mold life becomes a key consideration. Ningbo NKT Tooling Co., Ltd. usually uses pre-hardened steel or heat-treated steel, and cooperates with surface strengthening methods such as nitriding and laser quenching to extend the mold operation cycle. Ordinary die-casting molds are used in small and medium batches in many scenarios, and the service life and maintenance frequency requirements are lower than those of motor-specific molds.

Different requirements for mold matching equipment

Motor die-casting molds are often equipped with high-tonnage and highly automated die-casting machines to improve production rhythm and molding consistency. The mold needs to reserve interfaces to match the core pulling mechanism, spray cooling system, automatic pick-up manipulator, etc. Most ordinary die-casting molds can be adapted to standardized equipment, without a large number of automatic supporting facilities, and have wider adaptability.

Differences in cost structure and delivery cycle

Due to the complex structure, high process precision, and strict requirements for mold steel, the manufacturing cycle of motor die-casting molds is generally longer than that of ordinary die-casting molds, and the cost is also higher. Ningbo NKT Tooling Co., Ltd. needs to invest more design resources, simulation analysis and multiple rounds of mold trial adjustments in the development of motor molds. The development process of ordinary die-casting molds is relatively streamlined, and the cycle and cost are more flexible.

How to determine whether the motor die-casting mold needs to be repaired or replaced?

Check the quality stability of die castings

The main task of motor die casting molds is to mass produce parts such as housings and end covers with certain precision and structural requirements. When it is found that die castings frequently have burrs, flashes, shrinkage holes, pores, dimensional deviations, etc., it may indicate that the mold is partially worn, the fit clearance is increased, or the cooling system fails. Ningbo NKT Tooling Co., Ltd. usually records the trend of these quality changes through regular sampling. Once a persistent deviation occurs, it should consider repairing or replacing part of the mold structure.

Whether the mold service life reaches the design upper limit

Before putting into production, each set of molds will evaluate the service life based on the mold steel used, the type of die casting alloy, the cooling structure and the production rhythm. For example, the design life of high-strength aluminum alloy molds is generally between 80,000 and 150,000 molds. Ningbo NKT Tooling Co., Ltd. establishes mold usage files, records mold data, and sets warning values. When the cumulative die casting times of the mold are close to the design life, even if the product is temporarily normal, a comprehensive evaluation should be initiated to determine in advance whether it has reached the replacement node.

Whether the main structure of the mold is deformed or cracked

Due to high temperature and high pressure, the die-casting mold of the motor is prone to stress accumulation in the mold cavity, slider, guide column, parting surface and other parts after long-term operation, resulting in cracks, collapse angles, thermal fatigue peeling and other problems. In particular, if the rotor cavity or axial center positioning structure is deformed, it will directly affect the assembly performance of the motor. Ningbo NKT Tooling Co., Ltd. usually uses magnetic particle inspection, fluorescent inspection or visual inspection after mold disassembly to determine whether the structure is abnormal. Once crack expansion or loose seal fit is found, it is recommended to repair or replace the damaged parts.

Whether the cooling and exhaust system is operating normally

Blocking of the cooling circuit inside the mold or carbon deposition in the exhaust groove will lead to uneven mold temperature distribution, die casting sticking, and increased cold insulation lines. Abnormal mold temperature may also reduce the life of local molds. Ningbo NKT Tooling Co., Ltd. will regularly clean and flow test the mold cooling channel, and check whether the exhaust groove is unobstructed and whether it needs to be reprocessed or adjusted. If it is found that the cooling efficiency is significantly reduced and the maintenance effect is not ideal, it should be considered to replace the cooling components or even remake the mold frame.

Does the wear of key accessories affect the assembly accuracy?

With the long-term operation of the mold, high-frequency moving parts such as sliders, guide sleeves, reset mechanisms, and positioning pins will wear out. The expansion of the fit clearance will affect the mold closing accuracy, causing cavity dislocation, and thus affecting the consistency of product dimensions. Ningbo NKT Tooling Co., Ltd. uses gauges to detect the fit tolerance of these vulnerable parts during regular maintenance, and replaces accessories or re-matches the entire mold if necessary. If the assembly accuracy cannot be restored after replacement, it is more reasonable to replace the entire mold.

Whether the mold trial results can restore the design accuracy

After repairing the mold, the company often arranges a mold trial to verify the repair effect. If the product still cannot meet the dimensional requirements or the quality is unstable, it means that the mold damage has reached a critical state. At this time, the risk of continuing to use is high. Ningbo NKT Tooling Co., Ltd. will evaluate based on the complexity of the mold structure, maintenance cost and subsequent order volume. If the repair value is low, it will be recommended to directly replace the new mold.

Whether the mold maintenance frequency continues to increase

When the mold fails frequently in a short period of time, the maintenance cycle is shortened, and the maintenance cost rises, it means that the mold structure stability has declined. Frequent downtime not only affects production capacity, but also easily causes fluctuations in batch quality. Ningbo NKT Tooling Co., Ltd. recommends that once entering the high-frequency maintenance stage, alternative mold preparations should be planned in advance, and the old molds should be gradually phased out in combination with the production plan.

English

English 中文简体

中文简体