What are the electric drive series die-casting molds and what are their advantages?

Basic definition of electric drive series die-casting molds

Electric drive series die-casting molds are industrial molds specially used to manufacture electric drive system structural parts. They are mainly suitable for metal parts of key parts such as motor housings, electric control boxes, and electric drive modules in the fields of new energy vehicles, industrial automation equipment, and robots. It uses high-pressure die-casting technology to quickly inject metal materials such as aluminum, magnesium, and zinc into the mold cavity to achieve one-time molding to meet the production requirements of structural accuracy, strength, heat dissipation, and lightweight.

Background of the combination of electric drive system and die-casting molds

With the rapid development of new energy vehicles and intelligent manufacturing industries, higher requirements are placed on the structural design of electric drive components. Compared with traditional mechanical structures, electric drive systems need to integrate motors, controllers, heat dissipation structures, and connection interfaces in a limited space, which requires molds to be able to achieve complex geometry, thin-wall molding, and high dimensional consistency. The die-casting process is widely used because of its fast molding speed and strong structural integrity, making the electric drive series die-casting mold a key manufacturing tool.

Technical Strength of Ningbo NKT Tooling Co., Ltd.

Since its establishment in 2009, Ningbo NKT Tooling Co., Ltd. has focused on the design and manufacture of aluminum, magnesium and zinc alloy molds, and has rich experience in die-casting mold development. The company has a modern manufacturing workshop of 6,000 square meters and more than 80 employees, including more than 30 professional technicians and 15 mid- and senior engineers. It has the ability to produce more than 300 sets of high-precision molds annually, providing solid support for the development of electric drive system components.

High precision meets the assembly requirements of electric drive components

Electric drive molds usually involve multiple precision assembly surfaces, such as motor stator mounting holes, electronic controller interfaces, threaded seats, etc. These structures have high requirements for dimensional tolerances and positioning accuracy. Ningbo NKT Tooling Co., Ltd. uses high-precision CNC equipment and 3D mold flow analysis systems to optimize mold design and ensure that molded parts meet the consistency and interchangeability requirements of subsequent assembly.

Lightweight structure supports energy efficiency improvement

Electric drive systems play an important role in the lightweighting of vehicles. The mold needs to support the manufacture of lightweight parts with reasonable wall thickness and balanced mechanical structure. Through precise design and optimized flow channel system, Ningbo NKT Tooling Co., Ltd. reduces the weight of die-casting products while ensuring strength, thereby improving energy efficiency and reducing operating load.

Importance of heat dissipation structure design and mold matching

The electric drive system generates a lot of heat during operation, so shell-type structural parts often integrate heat sinks, cooling channels, etc. The electric drive series die-casting mold needs to accurately implement these design details in the mold cavity structure to ensure that the die-casting has good thermal management capabilities and extend the service life of the electric drive system. Ningbo NKT Tooling Co., Ltd. incorporates heat flow analysis and stress evaluation in the mold design stage to reduce dimensional errors caused by thermal deformation.

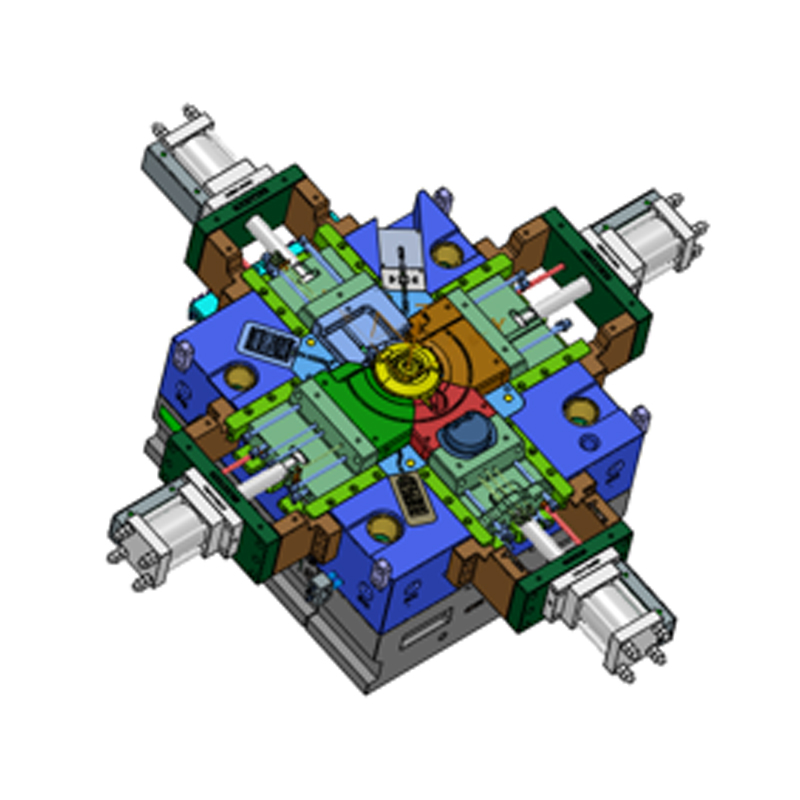

Support automation and multi-cavity production needs

Most of the electric drive system structural parts are used in conjunction with automated production lines, which have high requirements for mold stability, mold opening and closing rhythm, and product demolding smoothness. The electric drive mold designed by Ningbo NKT Tooling Co., Ltd. can be seamlessly connected with automatic die-casting equipment, support multi-cavity molding design, improve production efficiency, and adapt to mass manufacturing needs.

Compatibility with a variety of metal alloys

The electric drive mold not only supports aluminum alloy die-casting (such as ADC12, A380), but also other lightweight metal materials such as magnesium alloy and zinc alloy to meet the requirements of thermal conductivity, mechanical strength and processing performance in different scenarios. Ningbo NKT Tooling Co., Ltd. flexibly adjusts the mold heat treatment method and structural design strategy according to customer material selection to improve mold applicability and service life.

Equal emphasis on mold life and maintenance convenience

Electric drive molds need to operate frequently under high pressure and high temperature conditions, which poses challenges to the heat resistance and wear resistance of the mold. Ningbo NKT Tooling Co., Ltd. improves the stability and life of the mold by selecting high-strength mold steel, optimizing the mold cooling system, and applying surface treatment technology. At the same time, the mold structure takes into account the convenience of daily maintenance, which is convenient for quick replacement of wearing parts and reduces the risk of downtime.

Customized services to meet diverse needs

The design of each electric drive system may be different. Ningbo NKT Tooling Co., Ltd. provides customized full-process services from customer demand analysis, structural modeling, mold flow simulation, sample proofing to batch mold delivery to ensure that the mold can truly meet the dual requirements of product structure and production rhythm.

What is the difference between the electric drive series die-casting molds and ordinary molds?

Different application targets

Electric drive series die-casting molds mainly serve key components in the electric drive system of new energy vehicles, such as motor housings, electronic controller housings, electric drive module brackets, etc. Most of these parts involve electrical integration, heat dissipation, lightweight and other requirements. Ordinary die-casting molds are mostly used for traditional structural parts, such as home appliance housings, lamp brackets, tool accessories, etc. Their design goals usually focus on shape forming and mechanical support, and do not involve complex electronic control or thermal management systems.

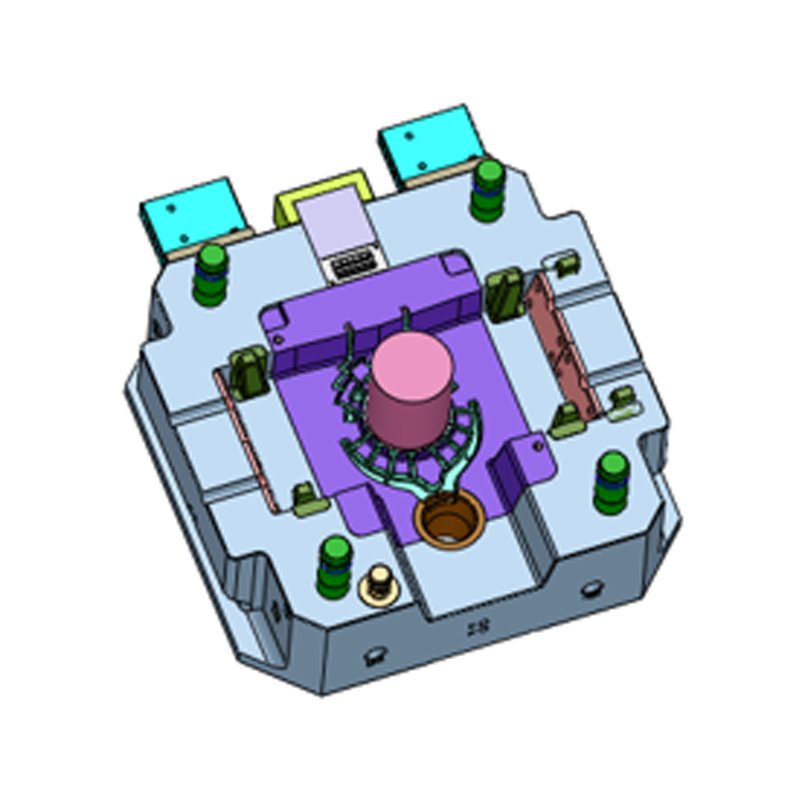

Higher molding accuracy requirements

Die castings in electric drive systems usually need to be closely matched with precision motor components, circuit modules and connectors, so the mold processing accuracy, dimensional tolerance control and repeatability accuracy have high standards. For example, the motor housing may need to meet the requirements of bearing seat coaxiality and stator installation size consistency. In contrast, although ordinary molds also have dimensional control, the overall tolerance requirements are relatively loose, allowing certain structural deformation and post-processing correction.

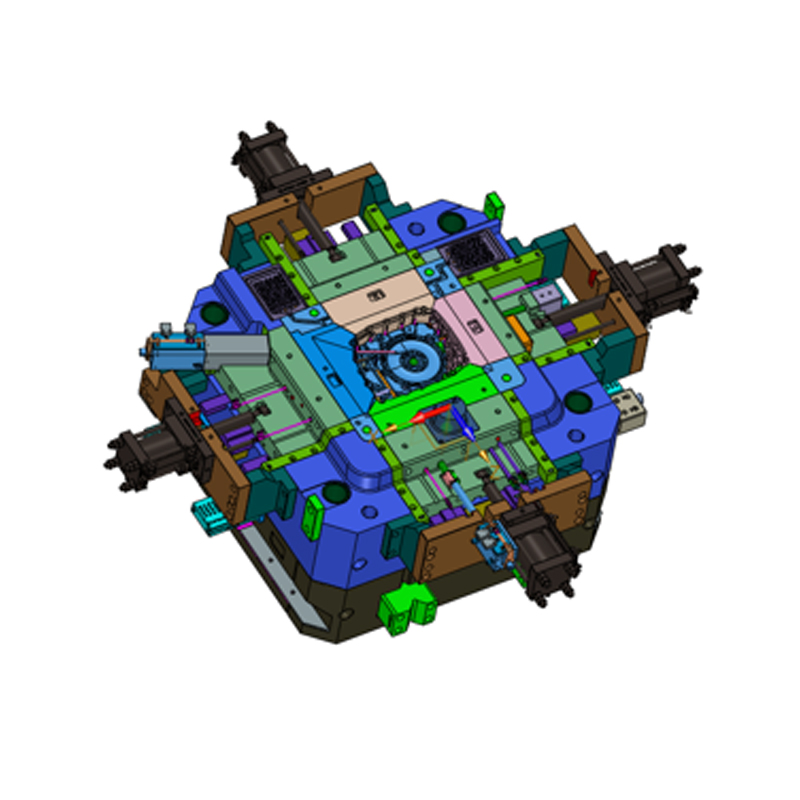

Different structural complexity

Electric drive molds involve multiple structural combinations, such as cooling channels, reinforcement ribs, mounting holes, cable outlets, integrated module interfaces, etc., and the structural design complexity is relatively high. Some molds also need to integrate inserts or multi-cavity designs to adapt to the automated molding process. Most ordinary molds are single-shaped cavities with simple structures, which are convenient for daily production and maintenance.

More attention is paid to heat dissipation and material flow design

In the development of electric drive molds, special attention is paid to the heat dissipation performance of castings, so mold design often includes heat dissipation fin area, cooling system layout and flow channel optimization. Ningbo NKT Tooling Co., Ltd. usually simulates the filling process through mold flow analysis to ensure that the alloy can be quickly and evenly filled in complex structures to avoid pores or cold shuts. Ordinary molds use more standard straight flow channels and simple cooling structures, focusing on production rhythm and cost control.

Higher standards for materials used

Electric drive molds are usually subjected to higher thermal stress, mechanical impact and frequency of use than conventional product molds. Therefore, the mold steel is mainly selected with high hardness, high temperature resistance and strong crack resistance, such as H13, 1.2344 ESR, etc. At the same time, in order to ensure the quality of die casting, multiple rounds of heat treatment and surface strengthening treatment may also be carried out. Ordinary molds are mostly based on cost-effectiveness, and the material selection standards and processing processes are relatively conventional.

Adaptability of supporting automation equipment

Electric drive series products are usually highly batched and suitable for use in automatic die casting and robot handling systems. Therefore, the mold structure needs to support automatic mold opening, ejection, cooling and rapid mold change mechanisms. Ningbo NKT Tooling Co., Ltd. will optimize the layout in combination with the automation level of the production line when designing electric drive molds. Ordinary molds are mostly used for manual operation or semi-automatic equipment, and have lower requirements for automation adaptation.

Different service life and maintenance cycle management

Electric drive molds require more stringent management of mold life due to stable product requirements and large batches. The vulnerable parts of the mold need to be replaced regularly, and the mold structure also needs to be easy to maintain and disassemble and inspect. Ordinary molds are flexibly allocated according to production batches, with relatively loose maintenance cycles and greater flexibility in service life management.

Long design and development cycle

Due to the variable structure and high requirements of electric drive die castings, mold development requires detailed three-dimensional design, simulation analysis, mold trial verification, mold repair and adjustment, and other stages, and the development cycle is relatively long. Ordinary molds have conventional structures, rich experience accumulation, more standardized development processes, and shorter delivery cycles.

Multi-process coordination capabilities

Electric drive molds often cooperate with subsequent machining, glue injection, coating, assembly and other multi-process processes, so it is necessary to reserve processing allowances and assembly positioning areas when designing molds. For example, some electronic control housings need to be designed in collaboration with PCBA boards to meet the coordination requirements of the overall assembly. Ordinary molds are mostly terminal use forms and do not involve too much subsequent process coordination.

Higher degree of customization

Due to the large differences in vehicle platforms, electric drive components are often highly customized in die casting. Mold development needs to closely cooperate with customer structural solution adjustments and flexibly respond to differences between different platforms and batches. Ningbo NKT Tooling Co., Ltd. often adopts a one-to-one engineering support model in such projects. Ordinary mold products have a high degree of standardization, a high design reusability rate, and limited customization depth.

English

English 中文简体

中文简体