What is a magnesium alloy die-casting mold and what role does it play in industrial production?

Basic definition of magnesium alloy die-casting mold

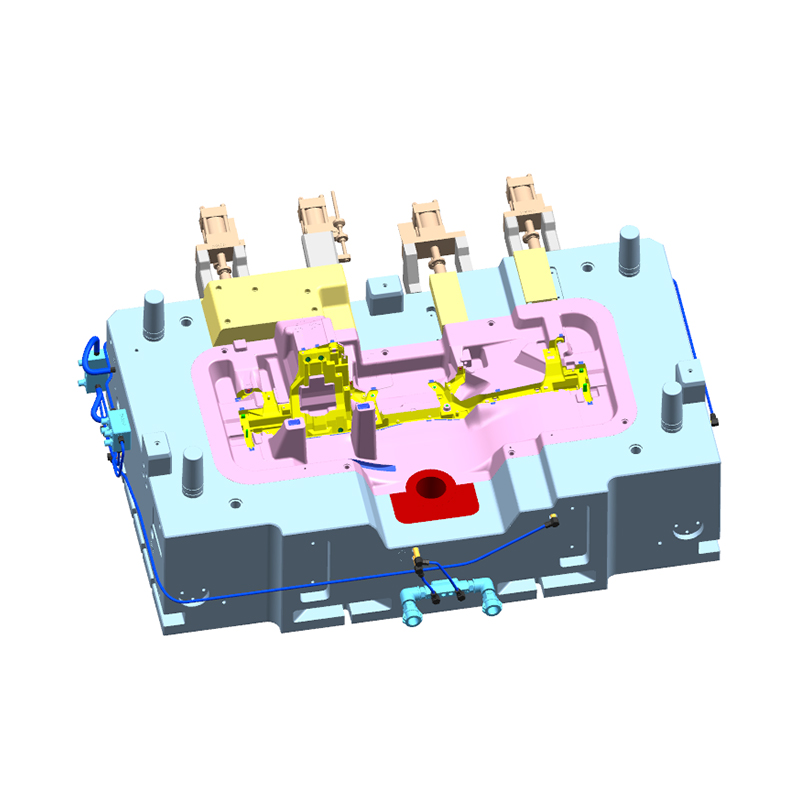

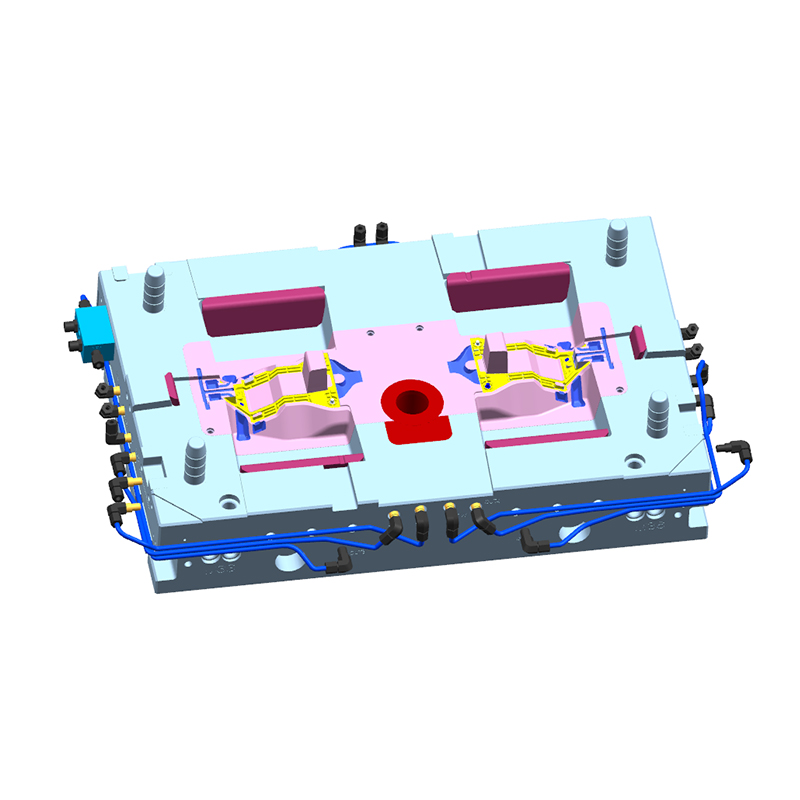

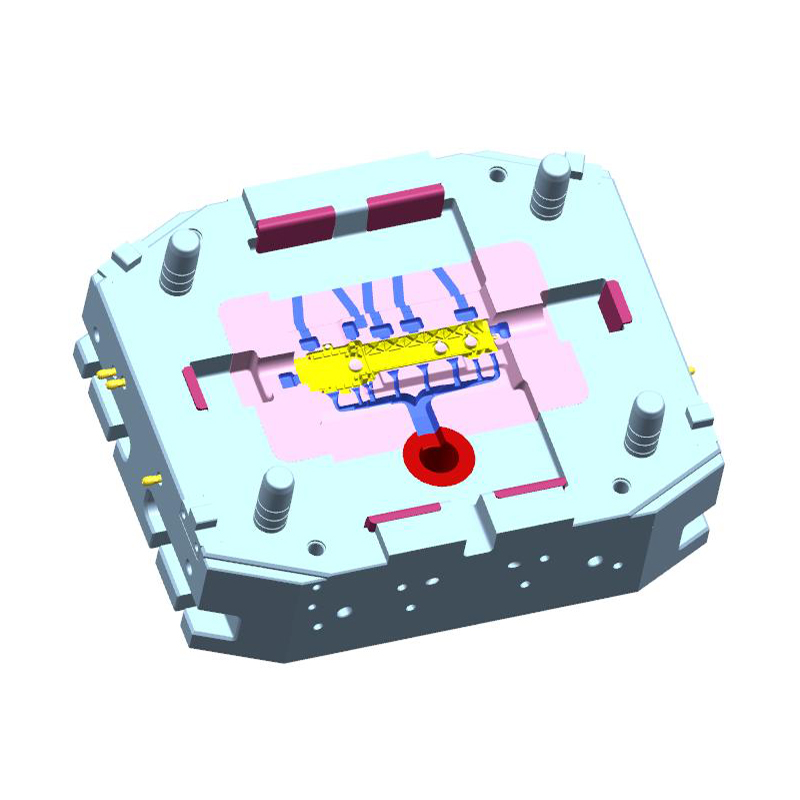

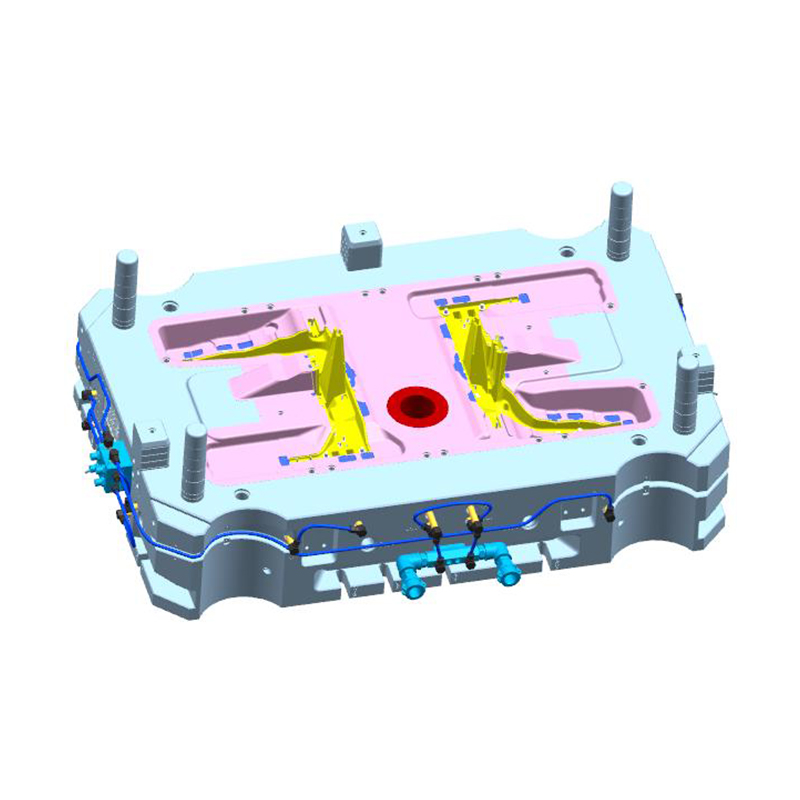

Magnesium alloy die-casting mold refers to a mold used to inject molten magnesium alloy materials into the mold cavity under high pressure and form them into structural parts through rapid cooling. This type of mold needs to have high thermal strength, thermal conductivity and anti-adhesion properties to adapt to the special process conditions in the magnesium alloy die-casting process. Due to the good fluidity and fast forming speed of magnesium alloy, the design of the die-casting mold also needs to focus on the comprehensive matching of internal flow channels, gates, exhaust and cooling systems.

Material selection characteristics of magnesium alloy die-casting mold

Magnesium alloy die-casting molds are usually made of hot working die steel (such as H13, 8407, etc.). These materials have certain high temperature strength and thermal fatigue resistance and can withstand frequent thermal cycle loading. In the mold manufacturing process, quenching, tempering, surface treatment and other processes are usually required to extend the service life and maintain dimensional stability. Reasonable selection of materials and heat treatment process directly affect the performance of the mold under high pressure and high temperature environment.

Structural characteristics of magnesium alloy die-casting molds

This type of mold structure is relatively complex, generally including functional units such as dynamic molds, fixed molds, cores, cooling water channels, core pulling mechanisms, and exhaust channels. Since the magnesium alloy die-casting process has high time requirements, the mold structure needs to consider the rapid filling and demolding mechanism to ensure the integrity of the surface of the part and the accuracy of the size. At the same time, the mold must also cooperate with the die-casting machine to have the ability to operate automatically to improve production efficiency.

Functional role of magnesium alloy die-casting molds in industrial production

In industrial manufacturing, magnesium alloy die-casting molds play the role of core tools for component forming. It not only determines the structural accuracy, surface quality and forming efficiency of die-casting parts, but also directly affects the subsequent processing and assembly matching of products. The stable operation ability of the mold is crucial for batch, standardized and automated production, especially in the application of automotive parts, consumer electronics, mechanical components and other industries.

Actual needs in typical application fields

In the field of automobile manufacturing, magnesium alloy die-casting molds are mainly used in steering system components, instrument brackets, body frame parts and other parts with high lightweight requirements. In the electronics industry, molds are used to form laptop shells, mobile phone middle frames, and structural brackets of portable devices. In industrial machinery and health and sports equipment, magnesium alloy forming components are also often used to reduce overall weight and improve structural strength. Ningbo NKT Tooling Co., Ltd. combines these actual needs to continuously optimize mold design structure and manufacturing process to improve the stability and adaptability of mold use.

The impact of mold technology on the performance of magnesium alloy materials

Magnesium alloy itself has good specific strength, low density and electromagnetic shielding ability, but it also has physical properties such as low melting point, easy oxidation and easy corrosion. Therefore, in the die-casting process, the mold not only needs to meet the molding accuracy requirements, but also needs to reduce the probability of defects such as pores, cold shuts and cracks through refined design. The temperature control system and exhaust system in the mold structure play an important role in this process.

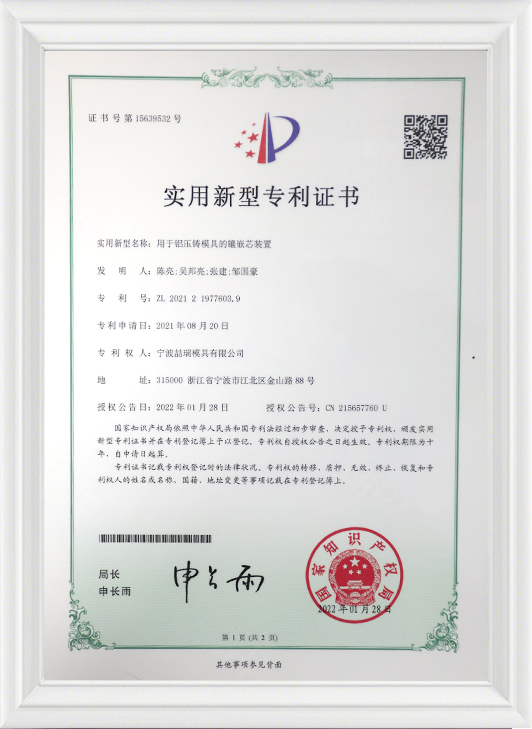

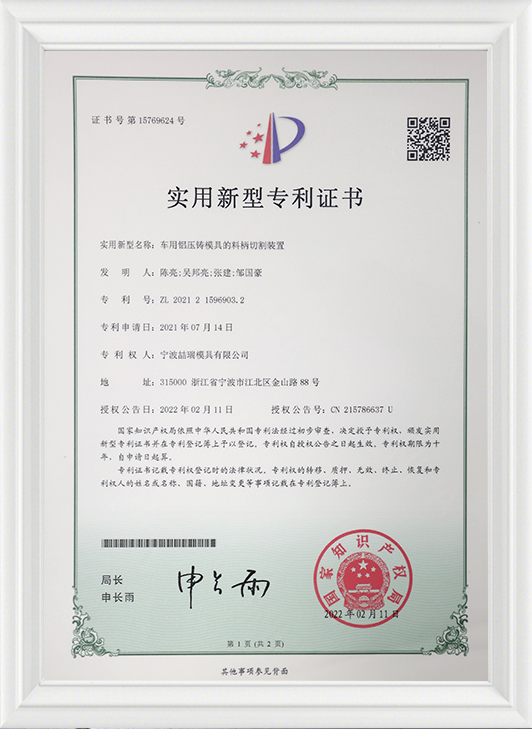

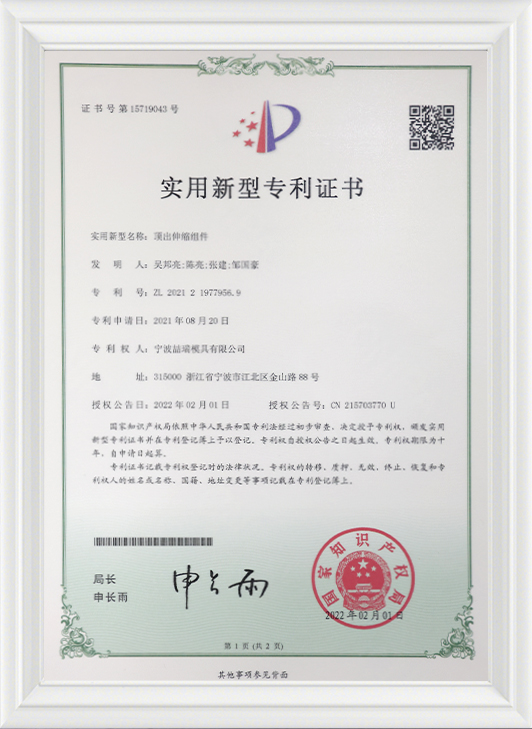

Ningbo NKT Tooling Co., Ltd.'s mold R&D capabilities

Ningbo NKT Tooling Co., Ltd. has strong mold R&D and manufacturing capabilities, equipped with advanced CNC machining centers, heat treatment equipment and mold flow analysis systems. The company has a technical team composed of middle and senior engineers who can customize various types of high-precision magnesium alloy die-casting molds according to customer needs. More than 300 sets of molds can be delivered each year, widely serving customers in multiple industries such as automobiles, communications, and industrial equipment.

Development trend of magnesium alloy die-casting molds

With the growing demand for green manufacturing and lightweight design, the application areas of magnesium alloy die-casting molds are constantly expanding, and the requirements are becoming more diversified. Future mold development will integrate more technologies such as digital design, simulation, intelligent monitoring, and modular manufacturing to improve the operating efficiency and adaptability of molds. Ningbo NKT Tooling Co., Ltd. is constantly promoting the integrated application of these new technologies to meet customers' diversified requirements for high-quality molds.

What are the daily maintenance recommendations for magnesium alloy die-casting molds to extend their service life?

Regularly check the wear of the mold surface

Magnesium alloy die-casting molds are used in high temperature and high pressure environments for a long time, and the cavity surface is easily affected by metal flow erosion and thermal fatigue. It is recommended that operators conduct visual inspections of key areas such as mold cavity, parting surface, core pulling structure, etc. after each shift to observe whether there are cracks, falling blocks, sticking molds, etc. If abnormalities are found, they should be repaired or replaced immediately to prevent affecting the surface quality of the die-casting and further damage to the mold.

Control the use temperature to avoid thermal fatigue damage

Temperature control is one of the important factors affecting the life of magnesium alloy die-casting molds. During the use of the mold, a reasonable preheating temperature should be set to avoid cracks caused by thermal shock caused by cold mold injection. At the same time, overheating should also be prevented during the operation of the mold to ensure stable operation within the process setting range. Ningbo NKT Tooling Co., Ltd. recommends using a temperature control system to monitor and adjust the mold temperature in real time to reduce the thermal fatigue effect.

Use appropriate release agents and lubricants

In order to prevent magnesium alloy from adhering to the mold surface at high temperatures and protect the mold surface, appropriate release agents should be used for lubrication. When selecting a release agent, attention should be paid to its thermal stability, coverage and volatility to avoid clogging the exhaust system or forming die-casting defects due to accumulation of residues. Regularly removing residues and oil stains on the mold surface can further delay the oxidation and corrosion process of the mold surface.

Reasonable control of die-casting process parameters

The service life of the mold is largely affected by the process parameter settings, such as injection speed, pressure, filling time, holding time, etc. If the parameters are set unreasonably, the mold will be subjected to excessive load in a short period of time, aggravating wear or deformation. Ningbo NKT Tooling Co., Ltd. recommends formulating a suitable process based on the specific structure of the mold and the characteristics of the magnesium alloy, and optimizing and adjusting it in combination with mold flow analysis tools to balance production efficiency and mold protection.

Keep the exhaust system unobstructed

Blocking the exhaust channel will cause gas residue in the mold, thereby affecting the surface quality of the die casting and increasing the surface load of the mold, thereby shortening the life of the mold. It is recommended to clean the mold exhaust groove and exhaust hole after each production cycle to ensure smooth exhaust of the gas. If the exhaust efficiency is found to be reduced, the local structure can be disassembled for deep cleaning, and the exhaust path can be reopened or optimized if necessary.

Regularly perform mold surface treatment and renovation

After the mold has been working for a certain period of time, its surface hardness and wear resistance may decrease, and it needs to be treated by re-polishing, plating repair or surface nitriding. For molds with high frequency of use or complex structure, it is possible to consider establishing a usage file to record each maintenance and renovation, so as to evaluate the trend of mold performance changes and arrange a scientific maintenance plan.

Do a good job of mold storage and rust protection

When the mold is not in use, it must be kept clean and dry, and coated with anti-rust oil or protected with a protective film. The mold should be stored in a well-ventilated area to avoid moisture, corrosion or impact. For long-term spare molds, the overall encapsulation and sealing can be carried out to reduce metal fatigue or surface aging caused by environmental changes.

Establish a standardized maintenance process and training system

To ensure the continuity and effectiveness of daily maintenance work, it is recommended that enterprises establish a complete set of mold maintenance standard operating procedures, including inspection frequency, project content, and division of responsibilities. Ningbo NKT Tooling Co., Ltd. focuses on the operational skills training of front-line employees in actual production, so that maintenance personnel can promptly identify abnormal mold conditions, handle them according to prescribed procedures, and reduce the risk of damage caused by human factors.

Evaluate the mold use cycle and replacement nodes

Although maintenance can effectively extend the life of the mold, each set of molds has its reasonable use cycle. Enterprises should combine factors such as mold structure complexity, material properties, and frequency of use to regularly evaluate the mold status and make replacement decisions for molds that have been severely worn or frequently repaired to ensure production continuity and stable quality of die-casting parts.

English

English 中文简体

中文简体