Aluminum Alloy Die-Cast Housing has become a cornerstone in modern manufacturing, offering high precision, durability, and efficiency for a wide range of industrial applications. Aluminum Alloy Die-Cast Housing is widely used in automotive components, electronics, machinery enclosures, and consumer products due to its excellent mechanical properties, lightweight nature, and resistance to corrosion. Manufacturers increasingly rely on Aluminum Alloy Die-Cast Housing to provide robust and consistent parts that meet stringent industry standards while enabling cost-effective mass production. The high structural integrity and dimensional accuracy of Aluminum Alloy Die-Cast Housing make it an ideal choice for industries that demand reliable and uniform components.

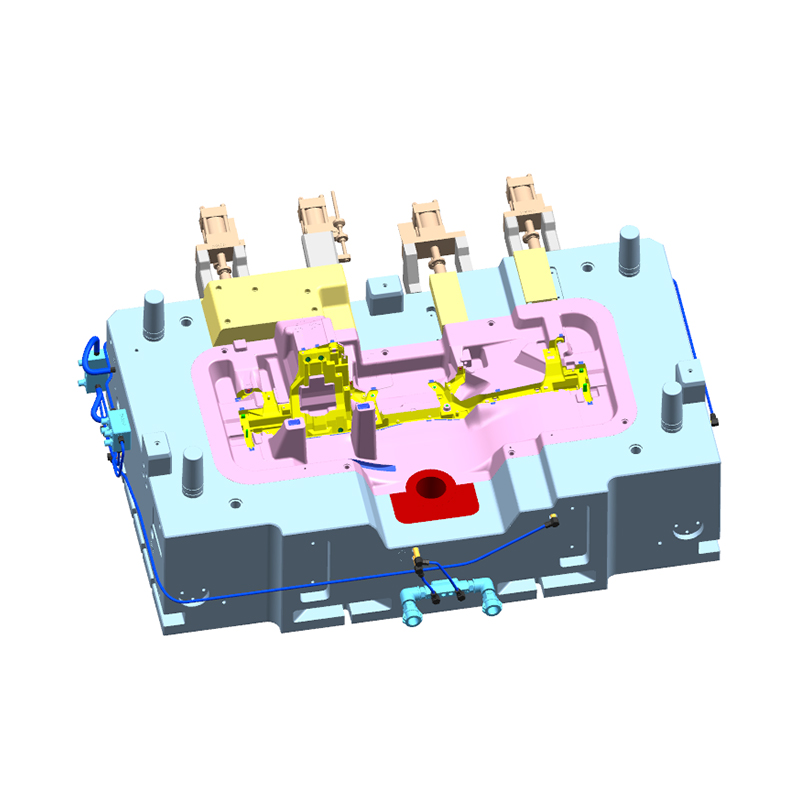

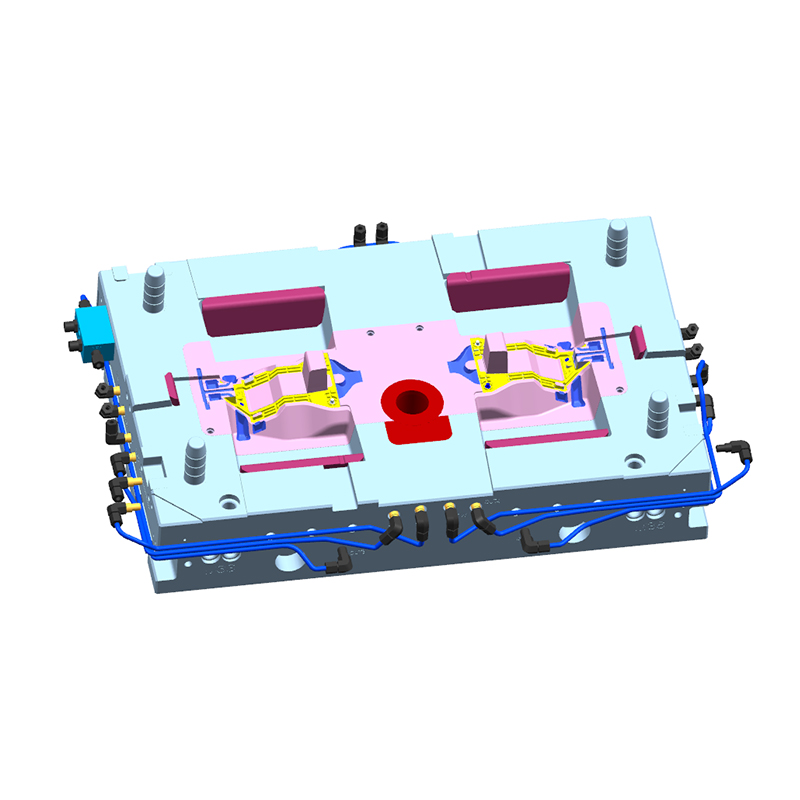

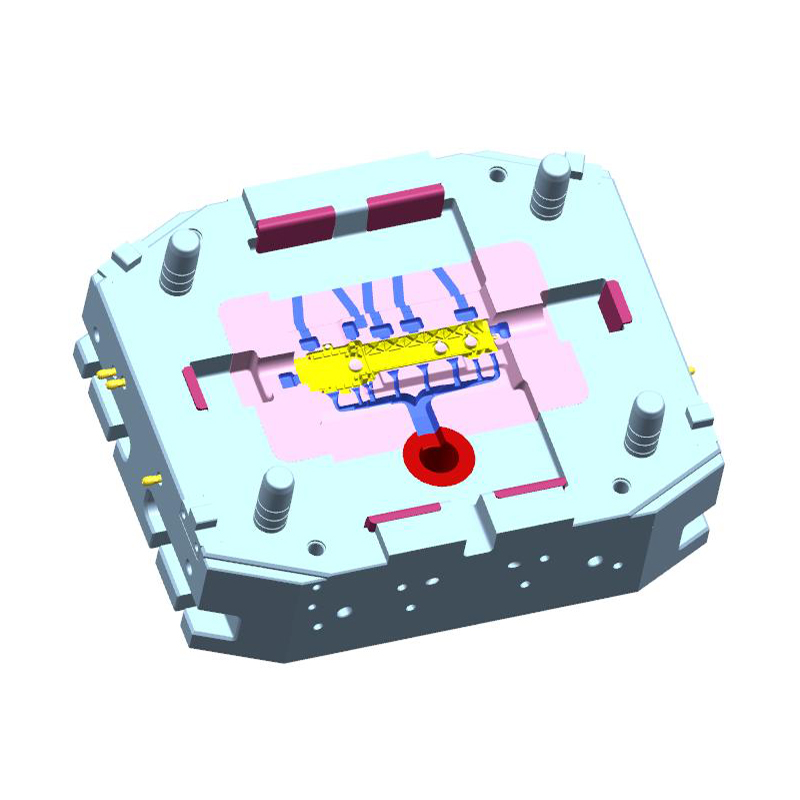

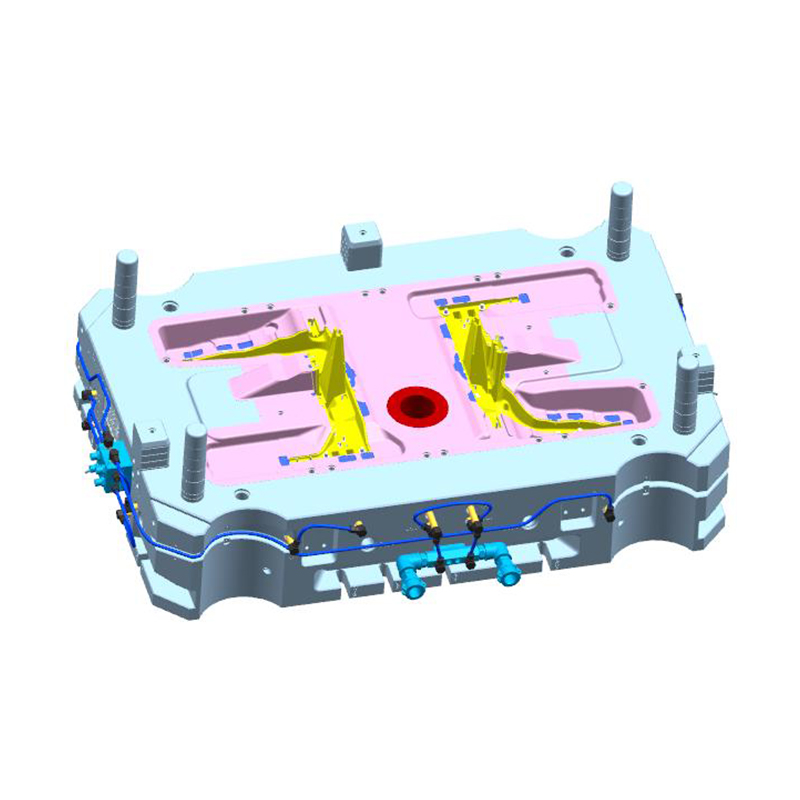

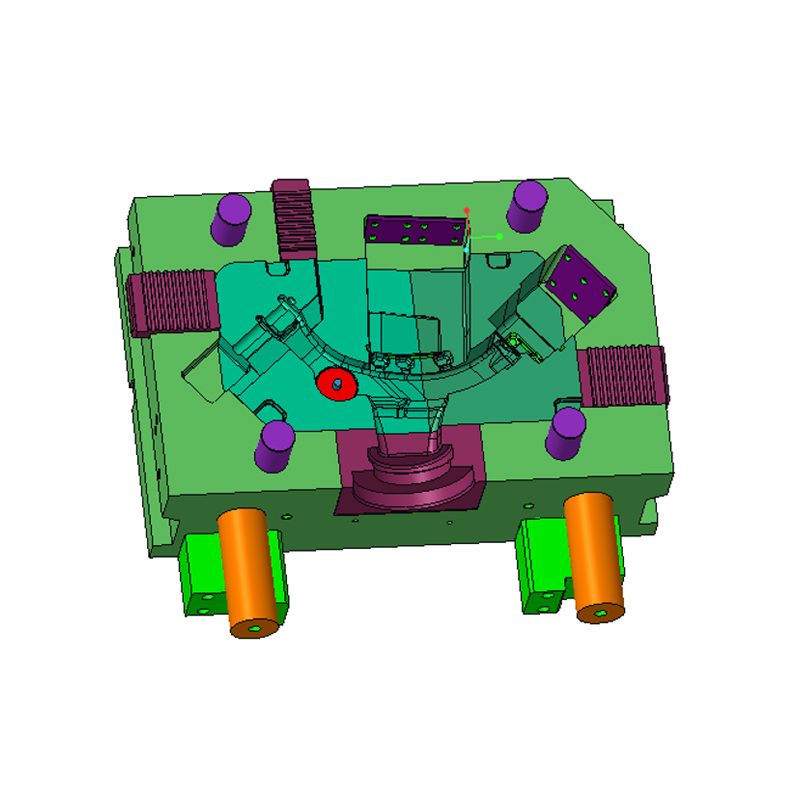

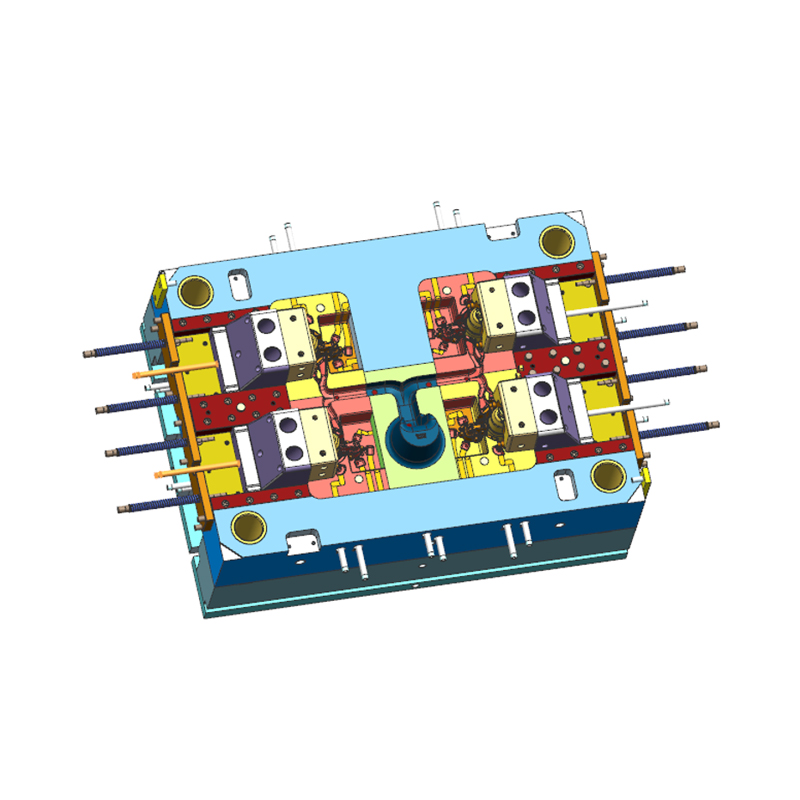

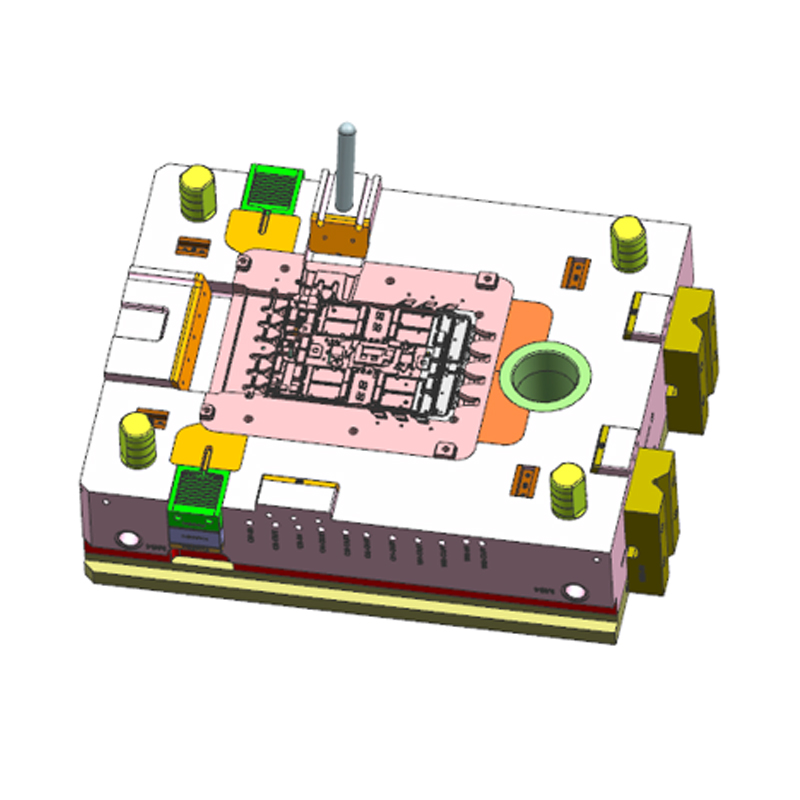

The 4-cavity design of Aluminum Alloy Die-Cast Housing molds significantly enhances production efficiency. By casting multiple parts simultaneously within a single production cycle, Aluminum Alloy Die-Cast Housing can reduce manufacturing time, lower labor costs, and improve overall operational throughput. This multi-cavity approach allows manufacturers to maintain high-volume production without compromising quality. Aluminum Alloy Die-Cast Housing produced with a 4-cavity mold benefits from uniformity across all pieces, ensuring consistent dimensions, mechanical strength, and surface finish. The reduced scrap rate associated with Aluminum Alloy Die-Cast Housing also contributes to cost savings and sustainable manufacturing practices, making it a practical solution for large-scale production.

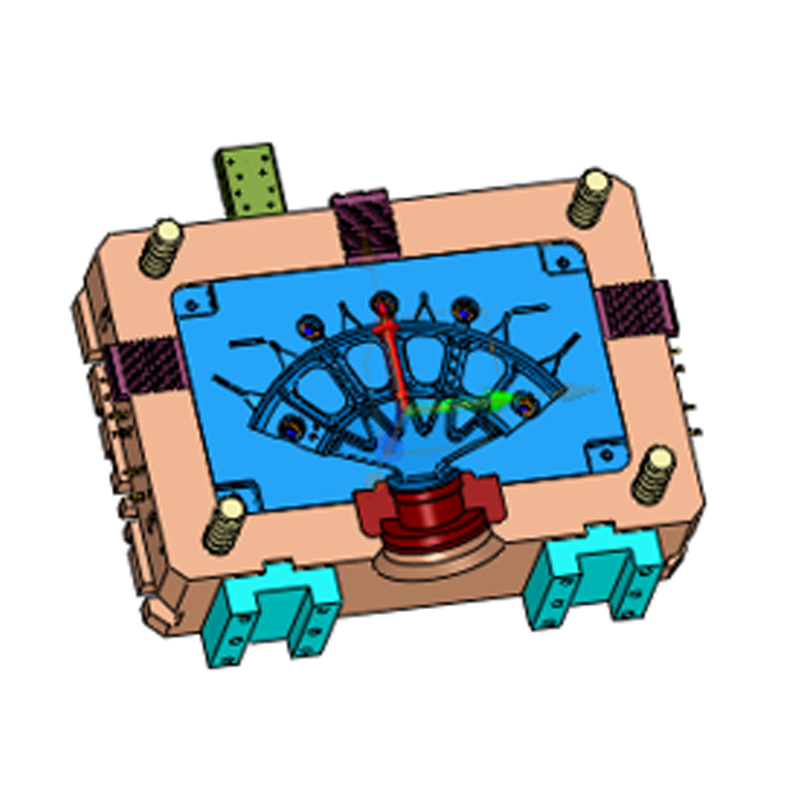

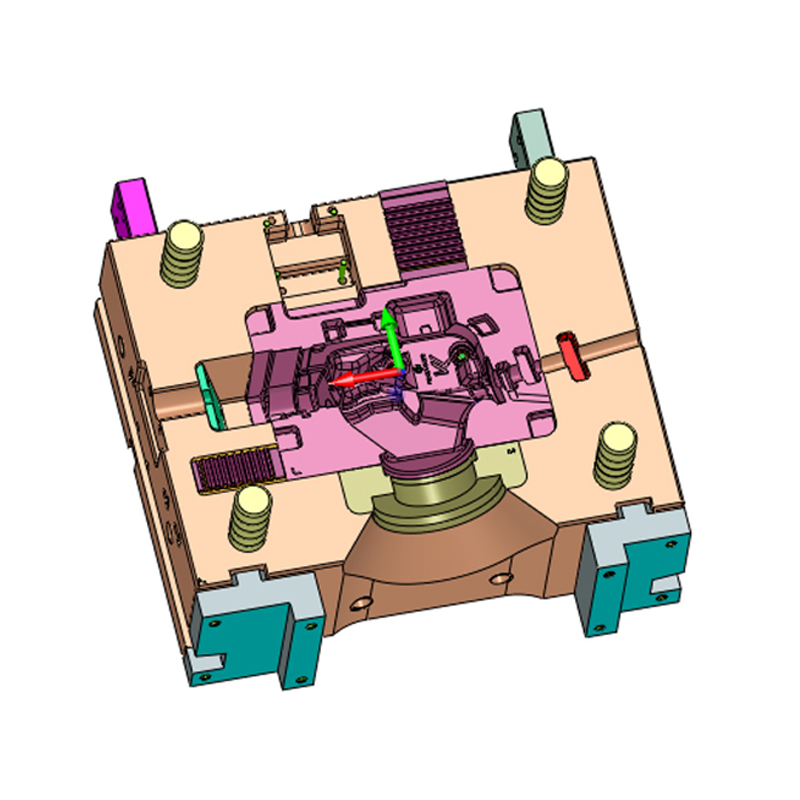

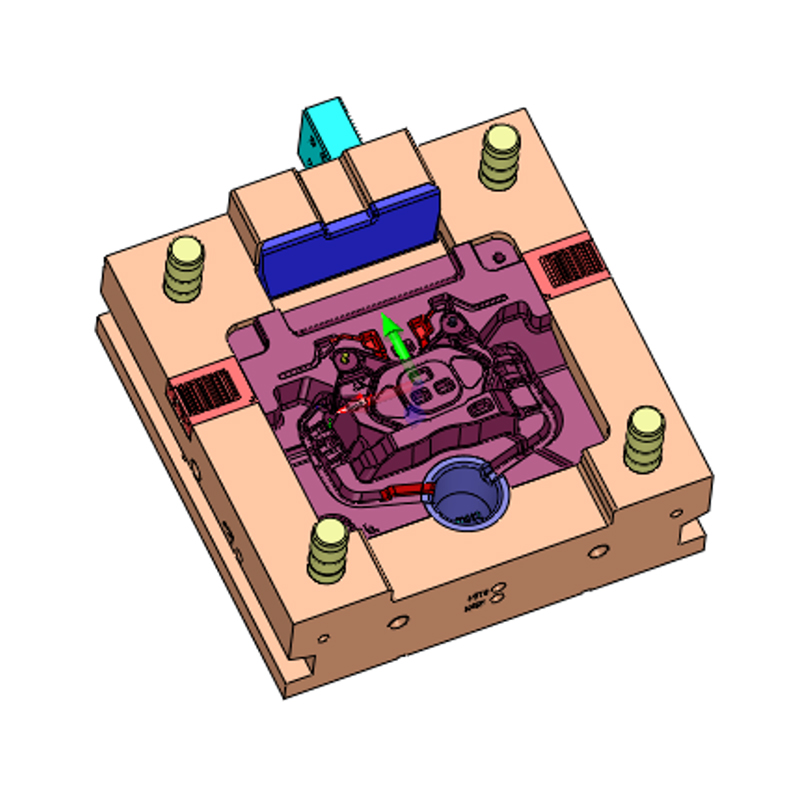

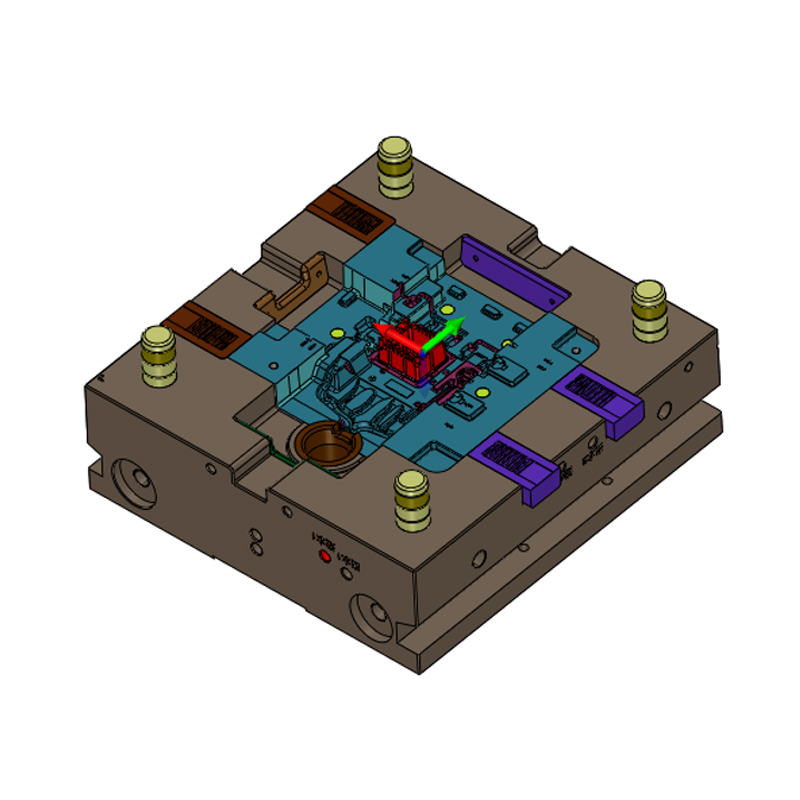

Aluminum Alloy Die-Cast Housing is engineered for precision and reliability. The die-casting process allows for tight tolerances, intricate designs, and smooth surfaces, which are critical for applications where fit and finish are essential. Aluminum Alloy Die-Cast Housing provides the ability to produce complex geometries that would be difficult or costly to achieve through other manufacturing methods. The lightweight yet strong properties of Aluminum Alloy Die-Cast Housing make it suitable for reducing the overall weight of assemblies while maintaining durability and structural integrity. Its corrosion resistance ensures long-lasting performance, even in harsh environments, which is particularly valuable in automotive, aerospace, and outdoor applications.

The versatility of Aluminum Alloy Die-Cast Housing extends to a wide range of surface treatments and finishes. Manufacturers can apply anodizing, powder coating, painting, or polishing to Aluminum Alloy Die-Cast Housing, enhancing its aesthetic appeal, corrosion resistance, and wear resistance. This flexibility allows Aluminum Alloy Die-Cast Housing to meet both functional and decorative requirements, making it suitable for consumer electronics, home appliances, and decorative hardware. By combining high-precision die-casting with customizable finishes, Aluminum Alloy Die-Cast Housing delivers components that satisfy both engineering demands and market expectations.

Aluminum Alloy Die-Cast Housing also contributes to sustainable manufacturing efforts. The use of aluminum, a recyclable and abundant material, ensures that Aluminum Alloy Die-Cast Housing can be reprocessed and reused with minimal environmental impact. The efficiency of the die-casting process reduces material waste, energy consumption, and production costs, aligning with green manufacturing initiatives. Manufacturers that adopt Aluminum Alloy Die-Cast Housing benefit from both economic and environmental advantages, making it an attractive choice for industries looking to balance performance, quality, and sustainability.

The mass production capabilities of Aluminum Alloy Die-Cast Housing are complemented by the high durability and consistency of the die-casting process. The 4-cavity mold ensures that each piece of Aluminum Alloy Die-Cast Housing meets the same exacting standards, reducing the likelihood of defects and maintaining product reliability. This reliability is crucial for applications that require repeated performance under mechanical stress, thermal cycling, or environmental exposure. Aluminum Alloy Die-Cast Housing delivers components that are dimensionally stable, mechanically strong, and visually consistent, which simplifies assembly processes and enhances overall product quality.

Aluminum Alloy Die-Cast Housing is highly adaptable to various industrial sectors. In automotive manufacturing, Aluminum Alloy Die-Cast Housing is used for engine components, transmission housings, and structural parts, offering weight reduction and improved fuel efficiency. In electronics, Aluminum Alloy Die-Cast Housing serves as protective enclosures for sensitive components, providing thermal conductivity, electromagnetic shielding, and aesthetic value. In industrial machinery, Aluminum Alloy Die-Cast Housing delivers structural strength and durability, ensuring long-term operational performance. The combination of versatility, efficiency, and precision positions Aluminum Alloy Die-Cast Housing as a preferred solution for diverse manufacturing needs.

Advanced manufacturing technologies enhance the production of Aluminum Alloy Die-Cast Housing. Computer-aided design (CAD) and simulation tools allow manufacturers to optimize mold design, flow channels, and cooling systems, ensuring high-quality Aluminum Alloy Die-Cast Housing with minimal defects. The integration of automated production lines and quality inspection systems further improves consistency, efficiency, and traceability. These innovations in Aluminum Alloy Die-Cast Housing manufacturing reduce human error, streamline production processes, and deliver high-performance components that meet modern engineering standards.

Aluminum Alloy Die-Cast Housing represents the intersection of precision engineering, manufacturing efficiency, and material innovation. Its lightweight strength, corrosion resistance, and versatility make it an essential material for industries that demand reliability, performance, and cost-effectiveness. The 4-cavity die-cast mold design amplifies these benefits by enabling rapid production, high uniformity, and reduced waste, making Aluminum Alloy Die-Cast Housing a strategic choice for manufacturers worldwide. With continued advancements in die-casting technology and material science, Aluminum Alloy Die-Cast Housing will continue to shape the future of high-performance, cost-effective, and sustainable manufacturing solutions.

English

English 中文简体

中文简体