Contact Information

-

Wangshan Road, Jiangbei District, Ningbo, Zhejiang, China

Wangshan Road, Jiangbei District, Ningbo, Zhejiang, China -

86-135-64796935

86-135-64796935

Custom Solution

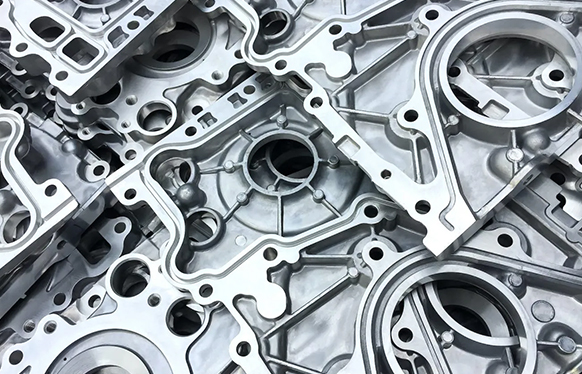

Promoting the die-casting mold industry

In the vast world of die-casting molds, Ningbo NKT Tooling Co., Ltd. has always been committed to creating accurate, efficient, and reliable mold solutions for customers. With many years of industry experience and a professional technical team, we provide customized mold solutions for many fields such as automobiles, electronics, and aviation.

Choosing NKT Tooling means choosing a reliable partner. We will provide high-quality mould solutions for your products with professional technology, excellent quality, and comprehensive services.

Advantages of Choosing Us for Customization

By cooperating with us for customization, you will get better quality molds, improve production efficiency, reduce processing costs, and ensure high-quality processing results. Our customized advantages will help customers gain competitive advantages in specific application fields and meet personalized processing needs.

High-precision customization

Professional technical support

Personalized service

Quality Management System

Certified to ISO 9001, ensuring comprehensive quality control throughout the entire production process.

Raw Material Control

Strict screening and testing to ensure raw material quality.

Production Process Control

Control every link in the production process to ensure stability and controllability.

Product Quality Inspection

Strictly inspect the quality of molds by national and industry standards.

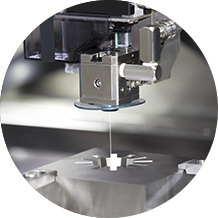

Precision Equipment

Advanced equipment guarantees mold accuracy and quality.

Perfect After-sales

Provide technical support, repair, and maintenance services.

One-stop service